Recently, the woodworking industry has ushered in a new breakthrough in the selection and design of dust collectors. According to experts, the layout, equipment model and safety requirements are the key factors in formulating a complete dust collector solution.

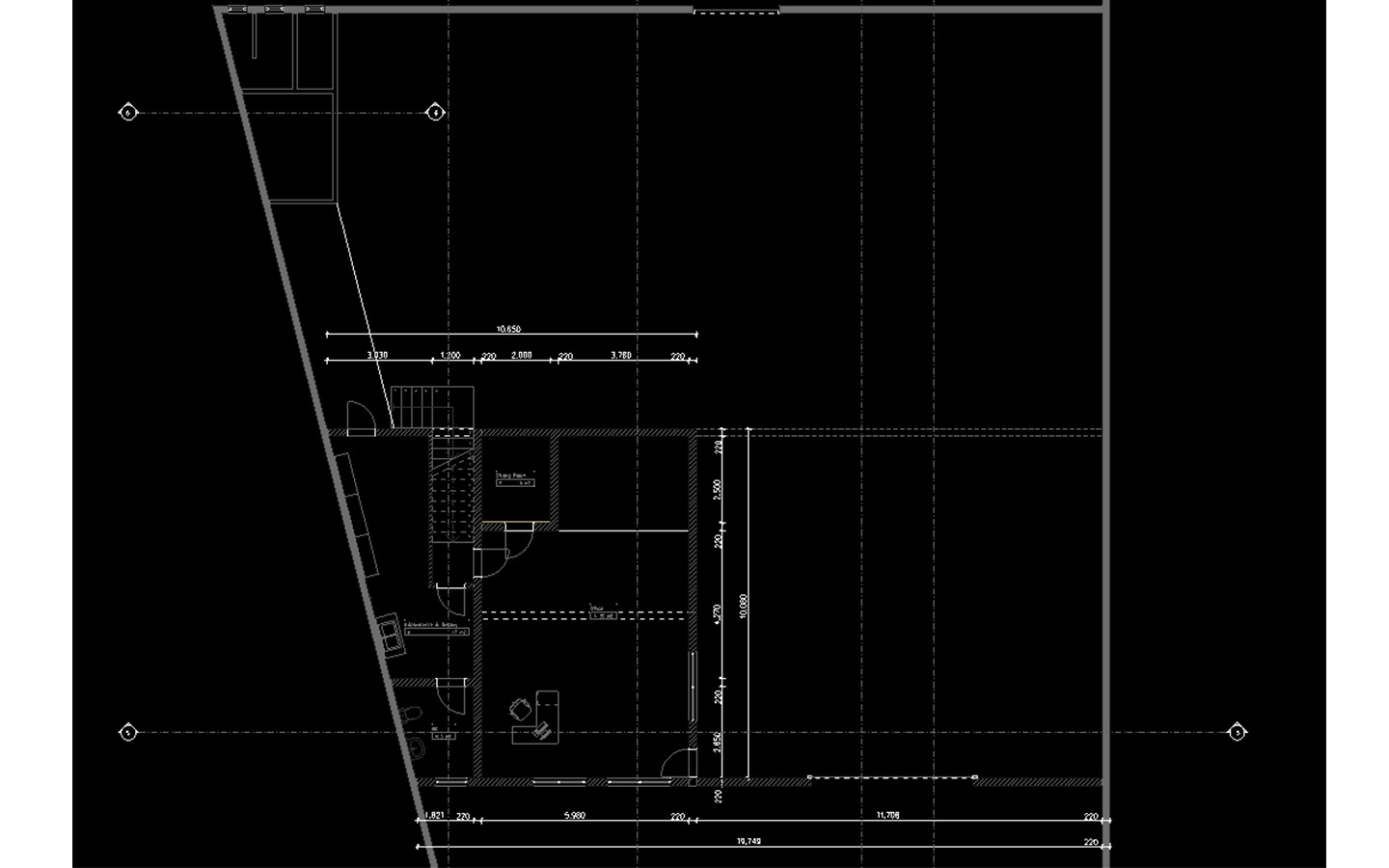

1.According to the suggestions of industry experts, if the layout drawing of the woodworking workshop can be provided, it will be helpful to the design of the overall scheme. The layout diagram can clearly show the size of the working area and the placement of equipment, providing a more accurate basis for selection. According to the layout drawing, experts can evaluate the number and diameter of dust removal ports of each equipment, and then determine the appropriate dust collector model and parameters.

2.However, if layout drawings are not available, there are other avenues that can help determine collector fit. By understanding the equipment models used in woodworking workshops, such as CNC, Double-Sided Machines, Milling Machine,Planing machine,Sanding machine,Wood texture wire brush machine,Wood texture embossing machine,Wooden line sanding machine,or the number and diameter of equipment dust removal ports, experts can conduct detailed analysis to ensure that the selected dust collectors can meet the needs.

3.In addition, electrical requirements are also one of the key considerations in the selection design. The electrical requirements of the woodworking dust collector include whether there are special requirements for the voltage and whether a specific brand of electrical accessories is required, such as Schneider, ABB, etc. In addition, some advanced dust removal systems may also require PLC (Programmable Logic Controller) to realize automatic control and monitoring functions. PLC can automatically adjust the operation mode and parameters of the dust collector according to the set program, improve work efficiency and reduce energy consumption.

4.Finally, in addition to the above factors, the selection design also needs to consider the safety requirements of the local government. This includes whether there are standards for noise, dust emissions, etc., and whether measures such as safety switches and overload protection are required. For example: Cameroon requires carpentry workshops to have a building structure that meets building safety standards to ensure stability and fire resistance. In addition, woodworking workshops need to be equipped with fire protection facilities and take fire prevention measures to reduce the risk of fire. Complying with Cameroon regulations and standards, installing a ventilation and dust collection system can help ensure compliance and avoid possible penalties and business interruption.

To sum up, the selection and design of woodworking dust collectors involves many aspects such as layout drawings, equipment models, electrical requirements, and local government safety regulations. Through scientific selection and design, the woodworking industry will be able to improve the quality of the working environment and achieve more efficient and safer production.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский