We have got the Ul, CE, ISO, SGS, certificates and all the motors are from world famous brands such as ABB, SIEMENS, WEG, TECO and etc., And there are many voltages for your choice such as 200V,208V,220V,230V,240V,380V,400V,440V,415V,480V.

Decent Machinery is one of the main large fan manufacturers in north China, which owns more than 180 employees and the production capacity of 12000 sets one year. There is an advanced Airflow Test Laboratory in our company. With the matured fan designing, testing, manufacturing technology, we can design and manufacture multipurpose fans according to users’ requirements.

We have got the Ul, CE, ISO, SGS, certificates and all the motors are from world famous brands such as ABB, SIEMENS, WEG, TECO and etc., And there are many voltages for your choice such as 200V,208V,220V,230V,240V,380V,400V,440V,415V,480V.

Decent Machinery is one of the main large fan manufacturers in north China, which owns more than 180 employees and the production capacity of 12000 sets one year. There is an advanced Airflow Test Laboratory in our company. With the matured fan designing, testing, manufacturing technology, we can design and manufacture multipurpose fans according to users’ requirements.

Thus, we are able to meet users’ complex and professional applications. Our products have been widely used in thousands of customers’

industrial systems, such as Coal-fired power, Metallurgy, Papermaking, Cement and Glass production, Chemical industry, Material handling, Sewage treatment, Waste incineration, Subway ventilation, Industrial boiler, and Dust removal systems etc.At present, Decent Machinery’ s customers distribute in these countries:

Thus, we are able to meet users’ complex and professional applications. Our products have been widely used in thousands of customers’

industrial systems, such as Coal-fired power, Metallurgy, Papermaking, Cement and Glass production, Chemical industry, Material handling, Sewage treatment, Waste incineration, Subway ventilation, Industrial boiler, and Dust removal systems etc.At present, Decent Machinery’ s customers distribute in these countries: EUROPE: British, Denmark, Italy, Romania, Russia, Ukraine.

ASIA: China, India, Indonesia, Israel, Korea, Malaysia, Pakistan, Philippines, Saudi Arabia, Thailand, UAE, Vietnam.AMERICA: USA, Mexico, Peru.

AFRICA: Egypt, Tanzania. 1. 24*7 hours online service

2. More than 100 customers visited us and felt very satisfied

3.Exported to over 80 countries

4.CE,ISO,SGS,ETA,MA,AMCA

5. Live video for the workshop by WhatsApp wechat or youtube.

6. Oversea technical support at the site

7. Better customers’ experience after sales: we visit our customer each year

8. Production according to your drawing(2D/3D)

9. Famous motor brand(Siemens/ABB/TECO/WEG)

10. High standard quality control- Testing video/Testing report available

11.Welding test report available

12. Materials testing available

13. Tracking number for each equipment available

—————————————————————————————————————————————————————————————–

Quality Control:

- Air Performance Testing

The data is measured by laboratory grade pressure transducers and rotary torque sensors of varying measurement range to accommodate the differing maximum horsepower and pressure to be measured. Each measurement is redundantly verified by other equipment within the test setup. A minimum of 8 channels of data is averaged for 5 seconds and collected for each data point along the curve.

- Sound Performance Testing

The data is measured by laboratory grade pressure transducers and rotary torque sensors of varying measurement range to accommodate the differing maximum horsepower and pressure to be measured. The sound is measured by a random incident microphone mounted to a rotating boom that revolves twice around in 64-second average. Each measurement of pressure and torque is redundantly verified by other equipment within the test setup. A minimum of 8 channels of data are averaged for 5 seconds and collected the point of operation being tested. This results in 2,000,000 points of data averaged for that single point figure 2 air data acquisition.

- Vibration Testing

Testing can be run for fans up to 500 horsepower motors

- Destruction/Deformation Testing

Testing is done in a horizontal shafted evacuated sealed 1-½” thick steel enclosure. Destruction is done for fiberglass reinforced plastic equipment. Deformation is done for steel and other metal impellers.

Testing is done in a horizontal shafted evacuated sealed 1-½” thick steel enclosure. Destruction is done for fiberglass reinforced plastic equipment. Deformation is done for steel and other metal impellers.

- Material Certification

All the material we use have the material test certificates so as to make sure a better quality for the production of the Decent fan blower.

- Wheel Balancing

Decent Machinery has the equipment and experience to dynamically balance our fan wheels, impellers, and rotors.. Known in the industry as a highly precise balancing system, we balance to meet a high standard. Dynamic Balancing reports and video can be provided to you up on your request.

- Weld Documentation

We can provide a range of weld documentation including weld maps, weld procedure specification (WPS), and welder qualification records with continuity reports. Our welders are qualified with welding operation certificates.

We can provide a range of weld documentation including weld maps, weld procedure specification (WPS), and welder qualification records with continuity reports. Our welders are qualified with welding operation certificates.

- Weld Inspection

A precise, strong weld is only as good as the quality control system involved and the final inspection of the part. Quality microscopes are at the heart of any inspection. While some weld issues can be seen with the naked eye, the majority require magnification to see. Decent Machinery has laid out with dozens of stereoscopic microscopes located in key areas that allow strategic inspection of parts as they’re processed.

- Leakage Testing

Decent Fan Blowers can provide leakage testing on fan assemblies that require low or zero leak performance. Our testing facility is capable of performing multiple types of factory pressure tests in order to further innovate low-leakage options for our fans.

- Safety Equipment

Safety equipment that is available includes belt guards, inlet and outlet guards, coupling guards, shaft and bearing guards, and weather cover guards. Nyb representatives can help assist in the selection of safety equipment for every Decent Machinery fan blower.

Safety equipment that is available includes belt guards, inlet and outlet guards, coupling guards, shaft and bearing guards, and weather cover guards. Nyb representatives can help assist in the selection of safety equipment for every Decent Machinery fan blower.

—————————————————————————————————————————————————————————————–

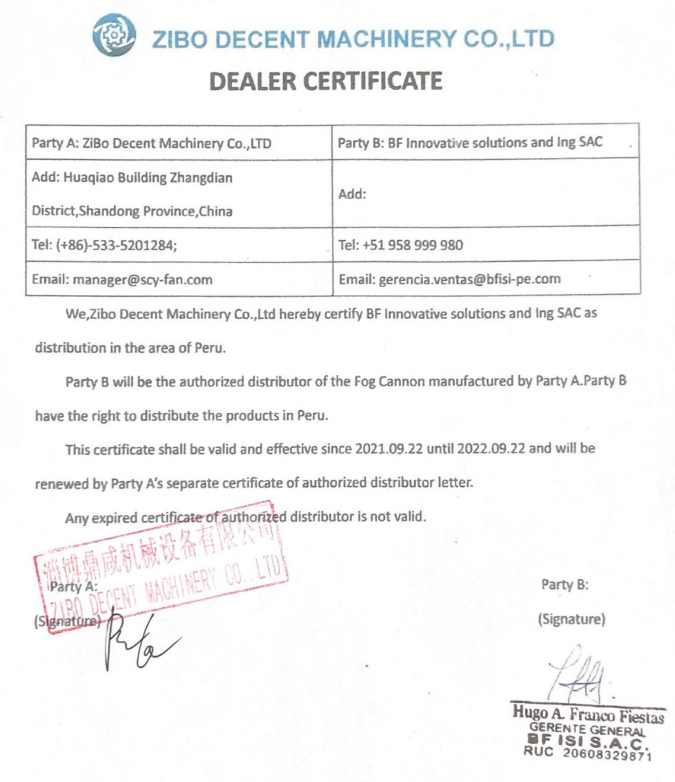

Agent in Pure:

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский