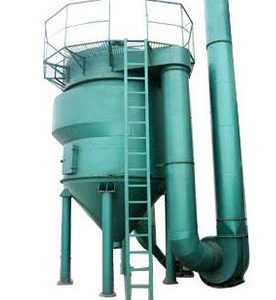

Centralized Dust Collection System can often do the work of dozens of smaller, individual air cleaners, providing dust collection solutions for the entire facility.

As polluted air is filtered waste dust is collected in bins or hoppers. Waste removal from one location is easier and thus more cost-effective. Systems generally consist of large media dust collectors with an initial separator used as a pre-sorter The pre-sorter removes large chips & coarse dust followed by the media filtration removing fine particles. Large chips & flakes collected in bins or drums. Filtration media often uses some form of cleaning such as mechanical shaking or a sudden pulse of air that knocks built up dust cake from the filters.

Our systems incorporate low-pressure drop across the unit resulting in less energy consumption. This feature reduces maintenance hassles and thereby lowering operating costs by using about 25% less than traditional units for cost-effective operation. Our units’ high-pressure nozzles and cleaning jets, reduces bag wear and dust penetration for greater cleaning power Units also offer sufficient spacing on every other row of hags to minimize fluidization of irregular dust. Depending on the application and available space, we are able to build and install a turnkey system to meet specific application requirements Some of its application areas falls in industries viz:

Cement Mills Steel plants Woodworking Power plants Paper Industries

Automobile plants

Our systems incorporate low-pressure drop across the unit resulting in less energy consumption. This feature reduces maintenance hassles and thereby lowering operating costs by using about 25% less than traditional units for cost-effective operation. Our units’ high-pressure nozzles and cleaning jets, reduces bag wear and dust penetration for greater cleaning power Units also offer sufficient spacing on every other row of hags to minimize fluidization of irregular dust. Depending on the application and available space, we are able to build and install a turnkey system to meet specific application requirements Some of its application areas falls in industries viz:

Cement Mills Steel plants Woodworking Power plants Paper Industries

Automobile plants

It is available with air capacity ranging from 2000 m3/h to 350000m.Vh with a system static pressure of upto 1000 mm w.g.

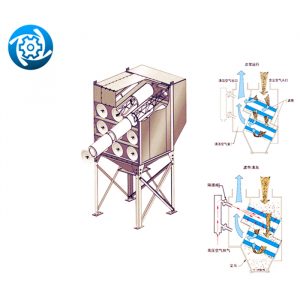

The DMC pulse bag dust collector is absorbing advantage of similar products from home & abroad,after improving and getting the new duster—Small bag duster.

The ash-cleaning of the duster is using pulse injection, it has good effects in ash removal, high removing efficiency, widely wind treatment, long serving life of filter bag, low maintenance, and reliable safe operation, etc. Advantages. The purification and material recovery of Non-fibrous industry dust are widely using in metallurgy, construction, machinery, chemicals, and diggings various industry enterprises.

| technical performance | Model | |||||

| PMD-24 | PMD-32 | PMD-42 | PMD-63 | PMD-72 | PMD-84 | |

| The total squire/m2 | 24 | 32 | 42 | 63 | 72 | 84 |

| The filtering speed/m.min-1 | 1.04~1.67 | 1.15~1.75 | 1.21~1.74 | 1.25~1.67 | 1.27~1.62 | 1.27~1.68 |

| Wind treatment consumption/m3.h-1 | 1500~2044 | 2500~3500 | 3500~5000 | 4700~6300 | 5500~7000 | 6500`8500 |

| Number/piece | 32 | 48 | 64 | 80 | 96 | 112 |

| Consumption/m3. min-1 | 0.032 | 0.048 | 0.064 | 0.08 | 0.096 | 0.11 |

| Entrance concentration/g.m-3 | ≤100 | |||||

| Export concentration/g.m-3 | <50 | |||||

| Plus press/M pa | 0.5~0.7 | |||||

| withstand negative/pa | 5000 | |||||

| Resistance | ≤1200

|

|||||

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский