Centrifugal fans are essential for efficient airflow in industrial settings, but operating them in extremely cold conditions can present unique challenges. To optimize their performance, we explore the benefits of incorporating split bearings and low-temperature motors into centrifugal fans. Join us as we delve into a real-life case study and reveal the power of these advanced technologies.

Case Study: Overcoming Challenges for Our Swiss Client

Recently, a Swiss client approached us seeking centrifugal fans. They expressed concerns about using water-cooled bearing housings due to limited access to circulating water and the risk of freezing in their outdoor installations. To address these challenges, we recommended the implementation of split bearings and low-temperature motors.

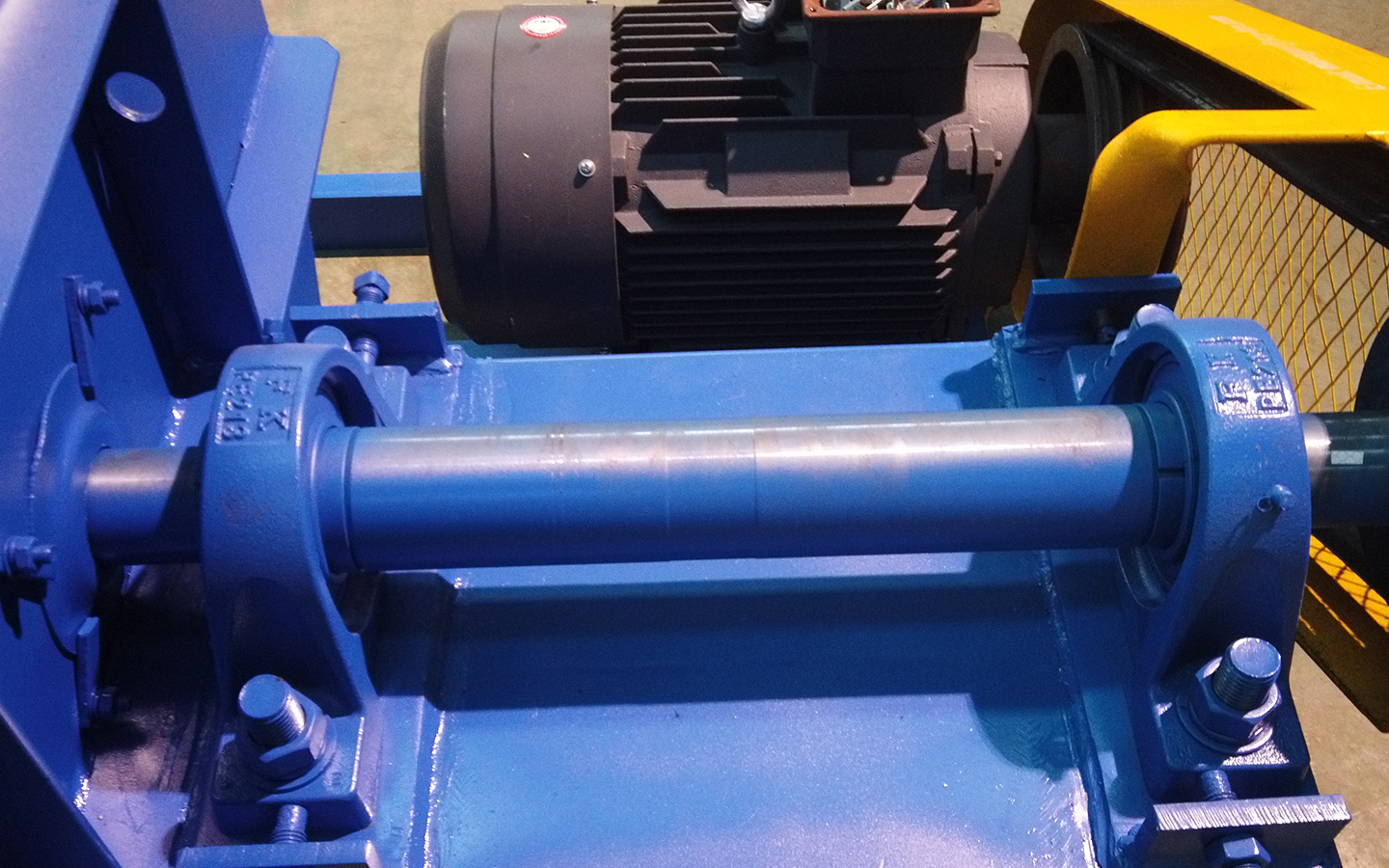

Split Bearings: Adaptability and Reliability in Any Environment

Split bearings offer an independent cooling and lubrication system, reducing dependence on external water sources. Unlike water-cooled bearing housings, split bearings excel in diverse environments, both indoors and outdoors. For our Swiss client, this solution provided exceptional reliability, eliminating the need for circulating water and mitigating the freezing risk.

Low-Temperature Bearings and Motors: Enhancing Reliability and Efficiency in Extreme Cold

In regions where temperatures can plummet to -40 degrees Celsius, low-temperature bearings and motors are indispensable. Engineered with specialized materials and sealing structures, low-temperature bearings effectively combat condensation and freezing, ensuring stable operation in frigid conditions. Moreover, low-temperature motors boast higher starting torque and superior adaptability, guaranteeing reliable performance in extreme cold.

By implementing our recommended solution, tailored to our Swiss client’s needs, they witnessed firsthand the reliability and efficiency of split bearings and low-temperature motors. This transformation led to improved production efficiency and seamless operations in their facility.

When it comes to optimizing centrifugal fan performance in frigid environments, selecting the right components is crucial. Split bearings and low-temperature motors offer independent cooling and lubrication systems, reducing reliance on water sources. By harnessing these advanced technologies, we empower your centrifugal fans to excel even in the most challenging cold conditions.

Connect with us today for customized centrifugal fan solutions that thrive in frigid environments. Let us optimize your production efficiency and ensure uninterrupted performance, no matter the cold conditions.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский