What is Air Handling unit(AHU)?

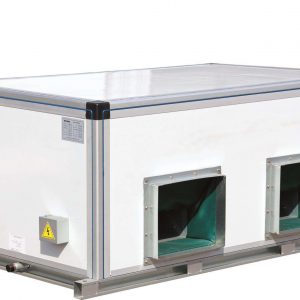

Air handling unit, generally called an AHU, is the piece of components mounted in enormous, open box-molded units called modules, which house the suitable ventilation prerequisites for filtering, air-molding or reestablishing the indoor air in a structure or premises.

They are normally introduced on the top of structures and, through conduits, the air is circled to arrive at every one of the rooms in the structure being referred to.

An air handler, or air handling unit (often abbreviated to AHU), is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system.An air handler is usually a large metal box containing a blower, heating or cooling elements, filter racks or chambers, sound attenuators, and dampers. Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the AHU.Sometimes AHUs discharge (supply) and admit (return) air directly to and from the space served without ductwork

AHU (air handling unit) covers vertical (air volume/flow from 2000 ~ 60000m3 /h), horizontal (wind increased from 2000 ~ 60000m3/h), and ceiling-type (air volume from 1000 ~ 16000m3/h) three series of air handler unit to meet customers’ need of cooling, heating, humidification, dehumidification and so on. It is widely applied in hotels, theaters, shopping malls, office buildings and a variety of places requires comfortable environment. It also can be used in electronics, chemical, medical, pharmaceutical, cigarettes, food, light engineering and other industrial buildings.

| Model | DM260-50HC | DM310-60HC |

| Clean Room Class | E | E |

| Quality Target | Temp. 20 °C – 22 °C, RH 55-60% | Temp. 20 °C – 22 °C, RH 55-60% |

| Capacity | 450.000 Btuh | 540.000 Btuh |

| Flow | 15.000 CFM | 18.000 CFM |

| Condensing unit | 50 HP ( 25 HP * 2 unit) | 60 HP ( 20 HP * 3 unit) |

| Static Pressure | 6″ WG (1500 Pascal) | 6″ WG (1500 Pascal) |

| ACH | 20 X | 20 X |

| AHU Unit | Double Skin PU foam 50 mm | Double Skin PU foam 50 mm, |

| Thickness 0.45 mm, Powder Coating. | Thickness 0.45 mm, Powder Coating. | |

| C/W: Magnehelic + Sight glass. | C/W: Magnehelic + Sight glass. | |

| Filters | Pre G4 + Medium F8 + HEPA H13 | Pre G4 + Medium F8 + HEPA H13 |

| Control Operation | Single Chip Microcomputer & Touch Keypad | Single Chip Microcomputer & Touch Keypad |

| Electric Heater | 24 kW (8 * @3 kW) | 24 kW (8 * @3 kW) |

| Flow Process | Mixing Box + Prefilter G4 + Medium filter F8 + Coil + Electric Heater + Fan + Hepa filter H13 |

Mixing Box + Prefilter G4 + Medium filter F8 + Coil + Electric Heater + Fan + Hepa filter H13 |

| Compressor | Panasonic | Panasonic |

| Volume Dumper | Fresh Air ( 1 pcs) | Fresh Air ( 1 pcs) |

| Volume Dumper | Supply Air ( 1 pcs) | Supply Air ( 1 pcs) |

| Volume Dumper | Return air ( 2 pcs) | Return air ( 2 pcs) |

| A、Partial material configuration of cabinet | ||||||||

| 1 | Frame | Insulating bridge aluminum alloy frame with imported sealing tape | ||||||

| 2 | Cabinet board structure and cabinet board insulation | It adopts double-panel structure, the inner and outer panels are made of color steel plates, and the outer panels are protected by transparent plastic film. The insulation material is high-pressure infused polyurethane, and the insulation thickness: 50mm | ||||||

| 3 | Mixing section | New and return air outlets with manual air volume regulating valve, with inspection door | ||||||

| 4 | Primary effect | G4 plate non-woven fabric primary filter | ||||||

| 5 | Medium-efficiency section | F8 bag-type non-woven medium-efficiency filter with Dwyer differential pressure gauge | ||||||

| 6 | Surface cooling section: | high quality copper tube blue wave aluminum fin direct expansion table cold coil tube with stainless steel water collecting pan | ||||||

| 7 | Heating section | Electric heater | ||||||

| 8 | Fan section | A. Italian brand NICOTRA /Zhejiang Lionke / Guangdong Detong fan

B. Siemens Beide/ Guangdong Jiangsheng Motor or equivalent brand Motor, C. with access door, window |

||||||

| 9 | Current sharing section | With current sharing plate, access door | ||||||

| 10 | High-efficiency section | H13 box-type high-efficiency filter with Dwyer differential pressure gauge | ||||||

| 11 | Air supply section | Air supply port with manual air volume regulating valve and inspection door | ||||||

| B.Main material configuration of refrigeration part | ||||||||

| 1 | Compressor | Japanese Panasonic compressor or equivalent brand (R407c refrigerant) | ||||||

| 2 | Condenser | Set of finned copper tube blue wave aluminum fins | ||||||

| 3 | Expansion valve | Shangheng | ||||||

| C.Main material configuration of electric control system | ||||||||

| 1 | Fan, motor starting device | Magnetic contactor, overload protection, high and low voltage protection, compressor phase loss protection, transformer | ||||||

| 2 | Temperature and humidity controller & temperature and humidity sensor | Deep Blue/British League or equivalent brand: (display in English)

Temperature controller controls temperature, with temperature display and setting functions,, Touch screen HMI interface monitoring |

||||||

| 3 | Electric control box installation | The electric control part is an independent electric control box. The wiring materials and wiring installation connection from the electric control box to the unit are not included. A separate quotation is required according to the actual installation location. The customer provides the power supply to the electric control box. | ||||||

| Power distribution system applicable power range 380V/3N/50HZ | ||||||||

| D.Size of unit | ||||||||

| 1 | DM260-50HC | Indoor unit size:5800*2000*1930

Outdoor unit size:2280*1060*1600*2sets |

||||||

| 2 | DM310-60HC | Indoor unit size:6000*2000*2280

Outdoor unit size:2280*1060*1450*3sets |

||||||

Why choose Decent Machinery?

Decent has been deeply involved in the design of HVAC products, and is familiar with the specifications and standards of various aspects of product design such as AHU, Air cooled chiller, water cooled chiller, valves, mufflers(Silencers) and other related parts. Can accurately grasp the design requirements of HVAC products, and complete the follow-up work efficiently and creatively. The Decent Machinery design team has keen observation, judgment and creativity, and can provide customers with 2D/3D design drawings based on the building layout drawings provided by customers to help customers experience our products and services more intuitively.

Our AHU Projects in South America:

The characteristics of air-handling units:

Frame structure: aluminum framework structure is adopted, which is made of high-strength aluminum alloy. Each corner of the framework is made of special castings, allowing the section bar to plug into it. This structure has the following features:

A: Good performance in mechanical strength, light in weight, corrosion resistance, beautiful shape and accurate size.

B: Flexible assemblage, very convenient to install, remove and maintenance. Also, it has longer service life than steel structure.

Panel structure:

A: The panel is formed by two layers of colored steel plates. Filler between the layers is high-density polyurethane or polystyrene, which has a better performance in thermal isolation than other materials like glass wool. No thermal bridge will be produced while working in all weather or working conditions.

B: Panels are fixed in a special way, with sealing material to strengthen its thermal and air resistance. This structure has the best performance in thermal isolation, noise reduction and intensity, so it can be used in places require high quality of air.

Fan, electrical motor:

A: Unit adopts centrifugal fan with both air inlet. The fan runs smoothly in the rigorous static and dynamic balance test.

B: With ball bearings sealed, and functions of pre-lubricating, self-aligning, self-locking, automatic thrust, etc., the fan is maintenance-free in normal use.

C: Fans of a small model unit are driven directly by external sub-motor, no belt, and easy to maintain.

Filter: unit filter is coarse plate. Filter material is cleanable convex Nylon net.

Cooler: the selected parameters of surface air cooler are designed by CAD/coi1 software. A standard cooler normally has copper pipes of φ6. It is tightened by an overall rise up of brass strung by corrugated aluminum fin tubes. Staggered copper pipes have good heat transfer performance, low airflow resistance and superior corrosion resistance, ensuring the cooler has a higher heat transfer coefficient and a longer life.

Note: 1. method to decide units type: facing the air inlet (i.e., along with air-flow direction), if the inlet and outlet tube is on the left, it is left form, if on the right, it is right form.

- According to client’s specific need, our company can configure additional electrical protection devices and air quantity speed regulation (including variable frequency controller and thyristor controller).

- Structures corresponding with the external air duct: as shown below, A is the default choice.

Ordering Guide

◆ Please be sure of the size, model, cool and heat quantity and left/right form in selecting air handling unit.

◆ Electrical controller is not part of the unit. However, the electric protector and air quantity speed regulation (including variable frequency controller and thyristor controller) is addable according to clients’ needs. Neither is inlet and outlet air quantity valve part of the unit. Please inform us before ordering if you need it.

◆ Our products are not limited to our routine units. According to clients’ special needs, unit can be equipped with additional electrical (auxiliary) heater, humidifier (steam humidifier, wet membrane humidifier, high-pressure spray humidifier and electrode humidifier), silencerand so on.

Our company follows the principle of constantly improving our products. Please kindly excuse us if we do not inform you in time about changes or improvement of product performance, specifications, and materials, and keep in touch with us to obtain the latest information.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский