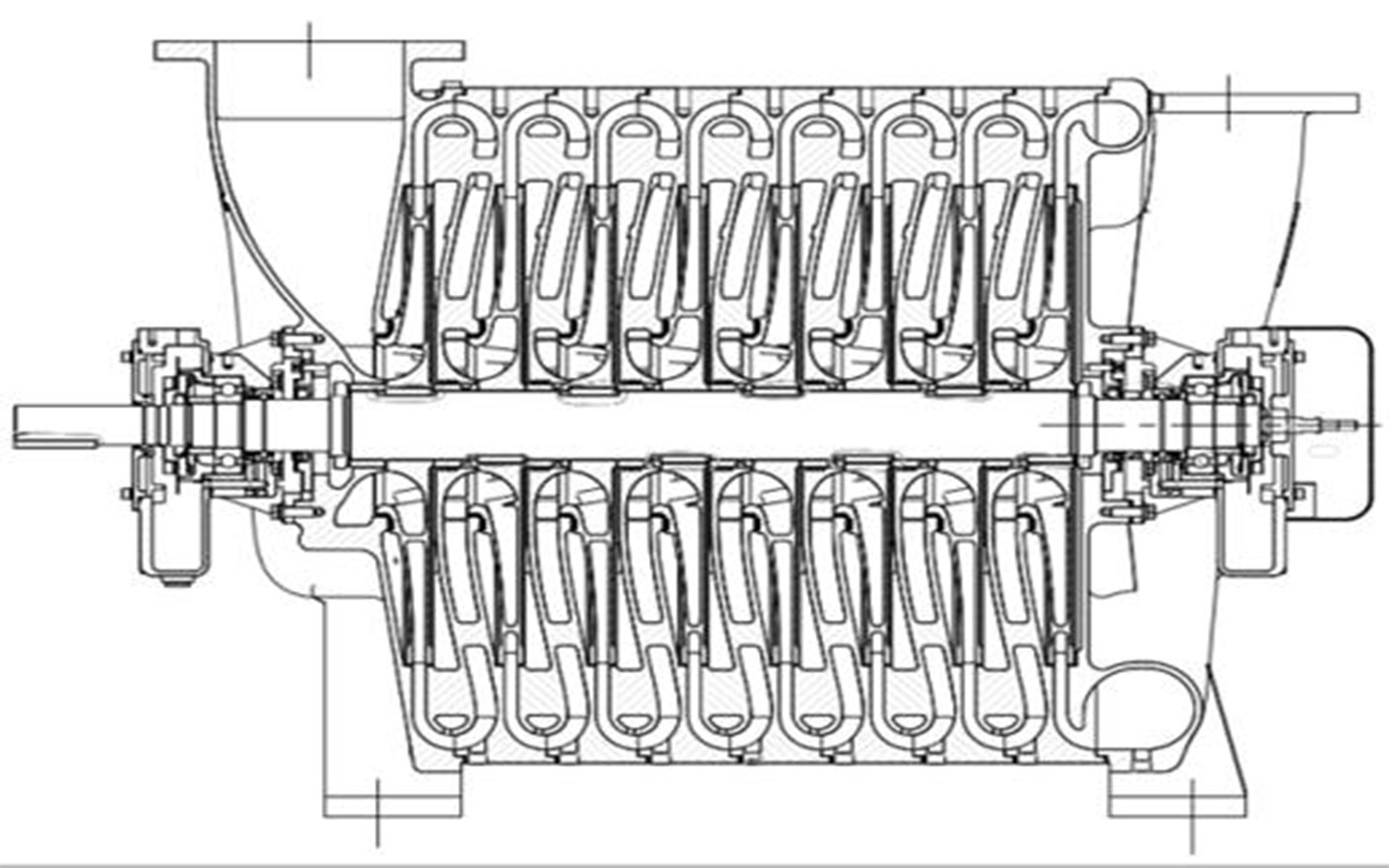

The multi-stage (casting) centrifugal blower uses a high-speed rotating impeller to do work on the gas, which increases the gas pressure and speed. The gas with a certain pressure flows out from the edge of the impeller at a higher speed and flows into the diffuser. The gas speed decreases and the gas Part of the kinetic energy is converted into potential energy, so that the pressure of the gas continues to rise. Then the gas flows through the bend and the return flow device and enters the next stage compression unit for continued compression. After being compressed by the multi-stage impeller, the gas that reaches the required pressure is discharged by the worm. The shells are collected and fed into the system through the exhaust port.

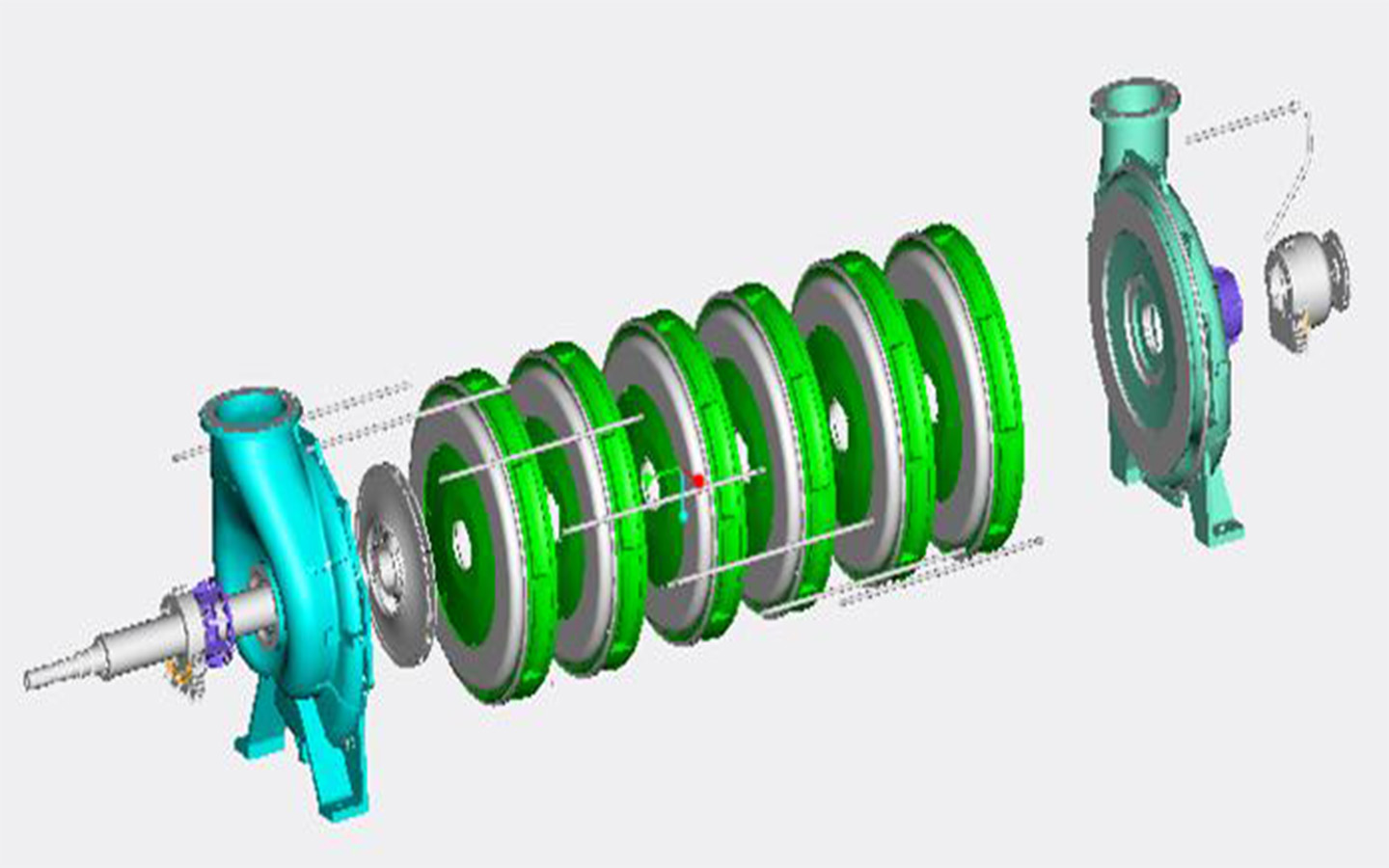

The main structure of the blower is a cast body, which is composed of an air inlet casing, an air outlet casing, an intermediate casing and an impeller. Generally, according to the customer’s flow and pressure requirements, the intermediate casing and impeller can be combined in series to form a 2 to 8-stage booster fan. Special Users can combine it to 10 levels, and the voltage boost can reach up to 120KPa.

The machine is directly driven by a variable frequency motor, and the blower and motor are directly connected by a coupling. The fan bearings are equipped with temperature and vibration sensors to prevent damage to the fan caused by excessive temperature or increased vibration. At the same time, lifting holes, hooks or lifting rings are installed on the blower body and base to facilitate installation and maintenance.

Noise and efficiency:

Flow channel design: Computer simulation technology is used to calculate and design the fan inlet flow channel, impeller flow channel, intermediate casing flow channel and exhaust flow channel to minimize the collision and friction between the air flow and the flow channel, so as to reduce noise and improve The role of efficiency.

Friction-free design: When the fan is running, there is no mechanical friction on other parts except the bearings, which not only reduces the noise, but also increases the service life of the blower. .

Multi-impeller combination: Each series of fans is designed with a variety of impellers to ensure the most efficient impeller combination. Personalized engineering design is carried out according to the user’s needs, so that the fan can maintain the highest operating efficiency within the flow range required by the user (single The efficiency can reach 95.3%) to achieve the goal of high efficiency and energy saving.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский