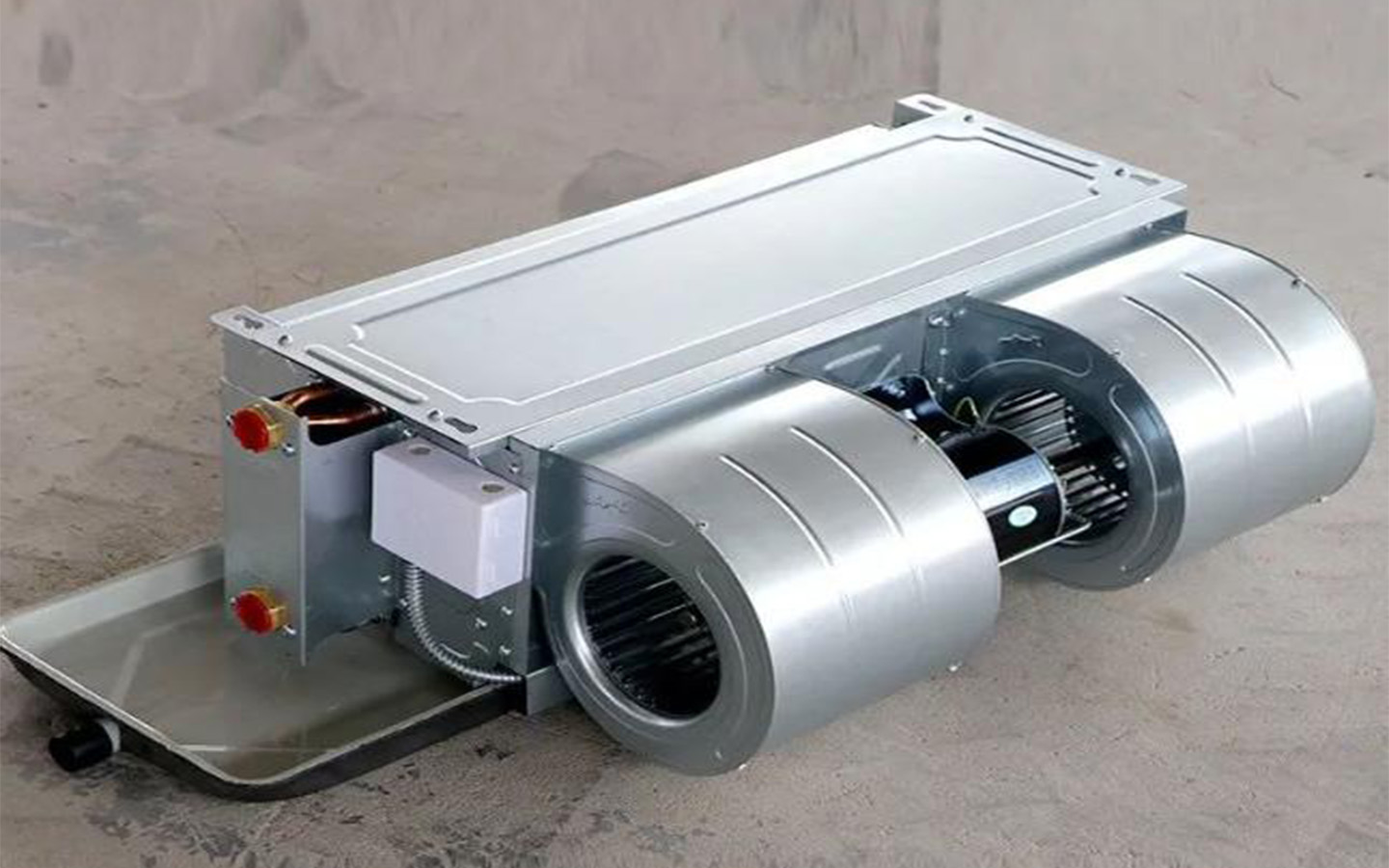

Fan coil system as a semi-centralized air conditioning system end equipment, with convenient construction, flexible control, adaptability and other characteristics, is widely used in hotels, restaurants and other multi-room air conditioning system. Reasonable selection of fan coil system not only directly affects the effect of air conditioning, but also to ensure the normal operation of the system and reduce the energy consumption of air conditioning is an important link in the actual operation of the project, the fan coil system often appear some faults, resulting in air-conditioned room load reduction, up to the design temperature requirements, etc.

1. Insufficient coil cooling capacity and solutions.

1.1 Design flaws and considerations fan coil system has two main performance indicators, namely, air volume and heat (cold) exchange, of which air volume is the dominant factor in determining the air conditioning effect. Therefore, to ensure sufficient air volume is a prerequisite to achieve the desired air conditioning effect. It should be noted that the air volume is the actual air volume of the system in normal use. Fan coiler nominal air volume and the actual air volume is a big difference, and in the specific engineering design is often based on the calculation of the cold load and by consulting the relevant manufacturer’s samples to choose the fan coiler system. At present, the product samples listed in the product’s nominal air volume is higher than the actual air volume. In actual use due to a significant reduction in air volume, directly affecting the heat transfer effect of the coiler, resulting in a drop in cold, the actual performance of the system (wind, cold) is lower than the nominal value of the phenomenon, so that the air-conditioning system does not reach the original design effect. Therefore, in the fan coil system selection, not directly according to the product performance table on the value of selection, to consider the actual performance and rated value of the deviation between the fan coil system to ensure that the actual amount of air supply.

1.2 Equipment failures and solutions fan coil system equipment failures, including filters, inlet water pipe, outlet water pipe and the internal copper pipe and other water piping blockage and coil scaling. At present, many hotels guest rooms fan coil system in the first two years of cooling effect is good, more than 3 years room temperature can not come down, mainly because: ① system return air is not equipped with air filters or return air filters, coil fouling, so that the performance of its heat transfer deterioration. System with 1 ~ 2 years on the accumulation of dust, and the more carpeted room the more serious the accumulation of dust. Usually, most of the fan coiler system for wet operating conditions, the dust in the air meets the wet surface of the coiler adheres to it, it is difficult to clean up. In order to enable the system to operate normally, to ensure indoor air quality, the need to add a high-efficiency filter in the return air inlet of the system or can be washed back to the air filter, forcing the indoor air through the filtration to remove the pollutants carried by the purification. ② system filters are clogged and not cleaned, resulting in excessive resistance, the air volume is small. Usually, the system horizontal concealed installation should be reserved for maintenance port, check the location and size of the port to meet the needs of maintenance, the filter should be able to regularly disassemble and clean up, otherwise it will result in the system due to clogging so that the air volume to reduce the amount of cold, the room temperature is not up to the requirements of cleaning, cleaning should be disassembled to clean the filters, and then open the inlet and outlet valves to release water, until the water is clean.

1.3 Improper construction and solution measures fan coiler system in the installation, first of all, should be installed firmly, level, and the connection with the upper and lower water pipes should be a metal hose connection, absolutely not in the pipeline connection to form an air pocket, otherwise it will cause the water flow is not smooth and lead to air conditioning effect decline. In addition, if the air outlet model is not properly selected, the air outlet is covered by decorations or blowing, suction air outlet is too close, the installation of the duct is too long or use too much hose, will lead to the system air volume or cold volume is insufficient. Therefore, when the system is installed, the air outlet should be set in the main place of indoor personnel activities, and the air inlet and exhaust outlet should be free of obstacles, and there should be a certain distance between the two, so as not to form the phenomenon of “short-circuit”. 1.4 Operation management Due to the chilled water supply temperature of the fan coil system, the state of the incoming air (temperature, humidity) and the change of air volume have a greater impact on the cooling capacity of the system. The cooling capacity of the system has a greater impact on the cooling capacity of the system, such as with the increase in the temperature of the chilled water, the system’s refrigeration capacity and dehumidification capacity will be reduced, resulting in the cooling capacity and dehumidification capacity are not up to the actual use of air-conditioning requirements. Therefore, fan coil air-conditioning system should be operated in accordance with the design working conditions in actual operation.

2. ceiling water seepage and prevention of fan coil system in summer is mainly used to give the indoor air cooling dehumidification, and then maintain a more comfortable indoor temperature and humidity, the moisture in the air from the fan coil system condensation out.

Therefore, the system on the one hand to be able to remove the moisture in the air, on the other hand, but also these condensate as soon as possible, to avoid water seepage or leakage due to maintenance is not in place.

2.1 Condensate pipe setting system construction due to the condensate disk tilt installation is not enough, the condensate pipeline is long and less bracket, can not guarantee the pipeline rigidity, condensate pipeline construction slope is not enough, etc. will cause the system to work when the condensate is not discharged smoothly and leakage phenomenon. Fan coil condensate are self-flowing discharge, condensate disk is very shallow and drainage residual pressure is very small. Therefore, we should do a good job of the slope of the drain, in order to prevent poor drainage leads to condensate overflow and wet damage to the ceiling decoration. For this reason, in the fan coil system engineering design process should strictly control the length of the water pipe, the arrangement of the pipeline should be full of “ventilation and air conditioning engineering construction quality acceptance specification” (GB50243-2002) condensate pipe slope is not less than 0.008 of the requirements of the condensate pipe diameter is slightly larger, set up a riser drainage, and improve the height of the ceiling. Diameter ≥ 20mm, and the choice of both corrosion resistance, but also to avoid condensation on the outside surface of the pipe of new materials, such as PVC-lined steel pipe, rigidity of the plastic pipe, ABS (plastic steel), etc., at the same time, try to set up a standpipe near the drainage, and improve the height of the ceiling.

2.2 Insulation problems fan coil system of chilled water supply, return pipe, condensate pipe and drip tray temperature is relatively low, in the summer there will be the phenomenon of surface condensation, so must do insulation.

However, in the actual construction, often appear on the condensate pipe does not heat preservation or insulation material selection and construction is not appropriate, such as connectors are not firmly connected, resulting in water pipe leakage or pipe surface condensation, affecting its use; or in the heat preservation did not put the insulation material tightly in the pipe, the air enters the aperture and touches the wall of the pipe will produce condensate, condensate accumulates in the aperture, the more it accumulates, it will be seeped out, will be the ceiling wet; there are also The project is the drip tray is not insulated, thus in the drip tray under the formation of the second condensation, wet ceiling. Specific treatment measures are: the inner wall of the coil, condensate tray outer wall insulation to be tight, in order to prevent condensation; in and out of the water branch pipe and valves, filters, etc. must be fully insulated, the best use of rubber-plastic foam insulation materials; main pipeline is appropriate to use polyurethane foam materials, the biggest feature of these materials is the low rate of water absorption and can be pasted with the foaming material, so that the board and the plate between the insulated shells are closely connected, will not leave construction seams, and the materials, the material is the most important feature is the low water absorption rate. There will be no construction joints, and the material itself is also waterproof, the surface does not need to do the waterproof layer, the effect is better.2.3 Drainage pipe blockage and solution Under the pollution and influence of indoor circulating wind, the bacteria in the condensate tray of the fan coil system continue to multiply, and mucilaginous filth will appear after a long time, which will result in the blockage of the drainage pipe, blocking the smooth discharge of the condensate. Therefore, the condensate pipe should be equipped with a cleaning port during construction, and the operation and maintenance personnel should insist on regular comprehensive inspection and cleaning of the condensate disk and condensate main pipe of all fan coil system when it is used in summer every year.

3. noise and noise reduction fan coiler system noise is the synthesis of pneumatic noise and mechanical noise.

Mechanical noise depends on the processing of rotating parts, dynamic balancing and assembly accuracy, that is, depending on the quality of the product, while the aerodynamic noise is only related to the static pressure of air supply and air volume. Usually, the pneumatic noise of the fan coiler is generally higher than the mechanical noise. In the actual operation of the system, the fan coiler system noise causes and solutions are: ① fan bearings run for a certain period of time, due to lack of oil, the noise will be significantly larger, by filling the lubricant noise will be reduced. ② system running for a long time, due to vibration and other reasons, resulting in the fan fixed bolts loose, resulting in fan shell vibration and noise increase, this situation can be solved by tightening the fixed bolts. ③ in the design and construction, fan coiler system due to improper selection, making the air volume is too large, while the indoor heat load is small, the air temperature difference is small, resulting in high relative humidity in the room, the temperature is low, the noise increases. Therefore, in the selection of ventilators, we should pay attention to the impact of the noise caused by the residual pressure, that is, in the use of high static pressure fan coiler system occasions should try to take anechoic measures. In addition, for some rooms with high static noise requirements, anechoic treatment can be done at the air outlet of the system or add anechoic devices. In addition, if the fan coiler is larger, you can add a section of 500 ~ 700 mm pipe silencer on the fan coiler to reduce noise. At the same time, the system should also pay attention to the installation of vibration damping and dynamic balancing and other work, vibration damping is generally used rubber shock absorbing hook.

4. Conclusion

With the increasing improvement of people’s living standards, the demand for fan coil system air conditioning will increase. In order to ensure the normal operation of the air conditioning system, really play a good effect, in addition to the requirements of the perfect system design, but also need to strictly control the quality of the construction phase of the project, timely and correct maintenance management of the system. In addition, in order to make the fan coiler system less faulty, the operator must be professionally trained, master the relevant theoretical knowledge, and pay attention to the method of maintenance in order to ensure the integrity of the system. Only from the engineering design, construction, operation and maintenance of the three aspects of active measures to make the fan coil system normal operation.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский