In explosive gas environments such as coal mines, fans, as important ventilation equipment, need to have explosion-proof performance to ensure safe production in mines. Explosion-proof mine fans are specially designed for such environments.

In explosive gas environments such as coal mines, fans, as important ventilation equipment, need to have explosion-proof performance to ensure safe production in mines. Explosion-proof mine fans are specially designed for such environments.

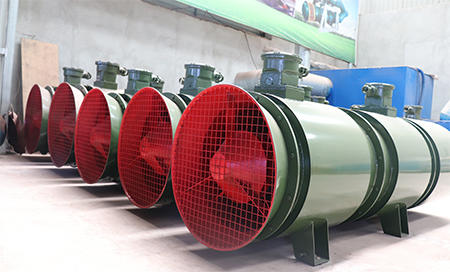

Explosion-proof mining fans are suitable for use in coal mines, metal mines, tunnels and underground buildings where explosive gases are likely to be generated. In these environments, any electrical equipment needs to have explosion-proof performance, so as to avoid explosion accidents caused by sparks. The explosion-proof mine fan can not only ensure the ventilation of the gas in the mine, but also effectively avoid the generation of sparks and ensure the safe production of the mine.

Explosion-proof mine fans are usually made of high-strength aluminum alloy or stainless steel. These materials have good explosion-proof performance and corrosion resistance, and can operate stably for a long time in harsh environments. At the same time, the impeller of the explosion-proof mining fan also needs to use special materials to ensure that it has good wear resistance and high temperature resistance.

Explosion-proof mining fans are mainly composed of motors, impellers, housings, guide vanes and other parts. Among them, the motor is the core component of the explosion-proof mine fan, which needs to have explosion-proof performance and high efficiency. The impeller is the main load part of the explosion-proof mine fan, which needs to have good hydrodynamic performance and strength. The casing is the shell part of the explosion-proof mine fan, which needs to have good sealing performance and corrosion resistance. The guide vane can adjust the air volume and air pressure of the fan to meet different usage requirements.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский