Introduction:

Woodworking workshops face significant challenges in maintaining a clean and safe working environment due to the accumulation of wood dust. At Decent Machinery, a leading provider of woodworking dust collection systems, we specialize in delivering tailored solutions that address the unique needs of our clients. In this article, we share a real-life success story that exemplifies how our comprehensive approach and collaboration with clients can transform woodworking workshops. From workshop design to client engagement, our professional expertise ensures optimal performance and enhanced productivity.

The Challenge: A Prominent Furniture Manufacturer’s Struggle

One of our notable clients, a prominent furniture manufacturing company in Turkmenistan, encountered persistent dust-related challenges that hindered their operations. The accumulation of wood dust compromised air quality, led to equipment malfunctions, and reduced overall productivity. Seeking a solution, they turned to Decent Machinery for our expertise in designing and implementing effective dust collection systems.

Analyzing the Workshop: A Comprehensive Approach

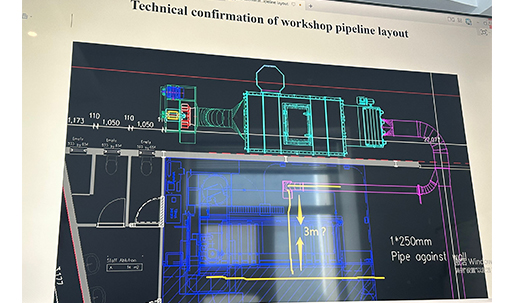

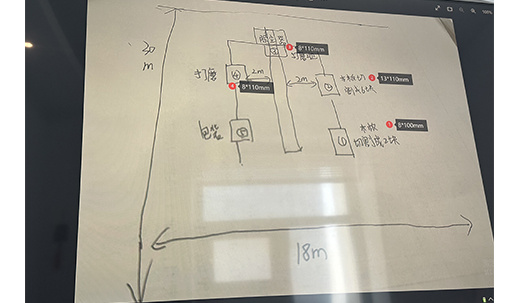

To address our client’s challenges, our team meticulously analyzed their workshop layout and equipment specifications. By closely collaborating with the client, we gathered crucial information such as equipment models, brands, layout, and exhaust outlet specifications. This collaborative approach allowed us to gain a comprehensive understanding of their unique requirements and tailor a solution that would optimize dust extraction and airflow management.

Designing the Solution: Customized Dust Collection System

Based on our analysis, we designed a customized dust collection system for the client’s woodworking workshop. We strategically positioned extraction points throughout the workshop, integrating high-performance dust collectors and optimizing airflow dynamics. This design ensured that airborne dust was efficiently captured at its source, significantly reducing health risks associated with wood dust exposure and preventing equipment malfunctions caused by dust accumulation.

The Transformation: Enhanced Efficiency and Productivity

After implementing our tailored dust collection system, the client witnessed a remarkable transformation in their woodworking workshop. Airborne dust levels were significantly reduced, resulting in improved air quality and a healthier work environment. Moreover, the reduction in dust accumulation prevented equipment malfunctions, reducing downtime by 40%. The client experienced a substantial boost in overall productivity, with a remarkable 35% increase.

Research-Backed Benefits: Validating the Results

The success of our customized dust collection system aligns with industry research that highlights the numerous benefits of professional dust control measures. According to studies published in the Journal of Occupational Medicine and Toxicology [1], efficient dust extraction systems can reduce airborne dust concentrations by up to 90%, leading to improved air quality and enhanced worker well-being. These findings, combined with the client’s success story, further emphasize the importance of investing in professional dust collection solutions.

Conclusion:

The success story of our client in Turkmenistan demonstrates the transformative power of our customized dust collection systems. By closely collaborating with our clients, we develop solutions that address their unique requirements and challenges. Our comprehensive approach, from workshop analysis to system design and implementation, ensures optimal performance, improved air quality, and enhanced productivity. Partner with Decent Machinery to experience the expertise and solutions that can revolutionize your woodworking workshop, creating a safer and more efficient working environment.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский