Air conditioning, or air conditioner, refers to the process of adjusting and controlling the temperature, humidity, cleanliness, speed and other parameters of the ambient air in a building/structure using manual means.

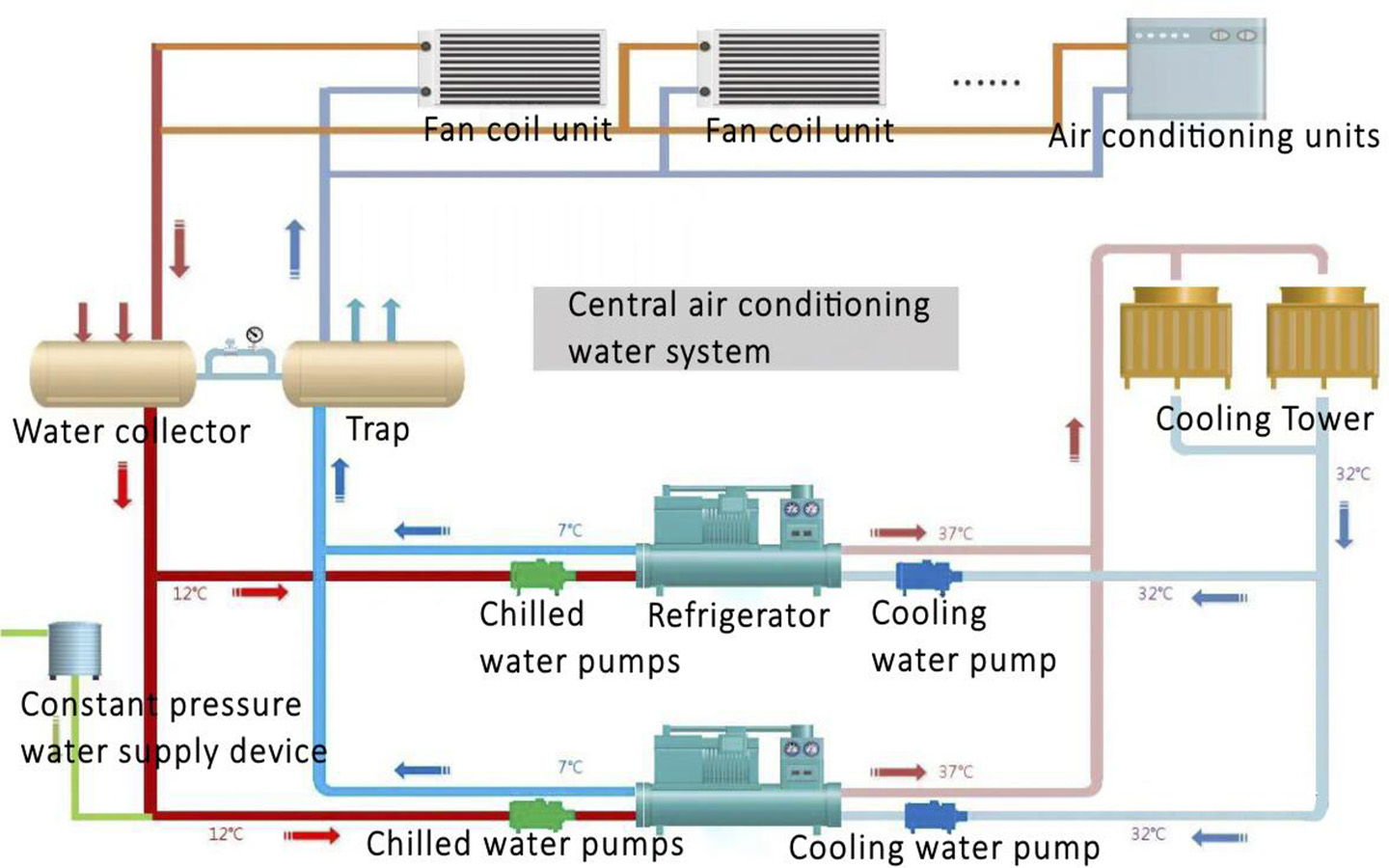

Central air conditioning: The central air conditioning system consists of a cold and heat source system and an air conditioning system. The principle of liquid evaporation refrigeration is used to provide the required cooling capacity for the air conditioning system to offset the cooling load of the indoor environment; the heating system provides heat for the air conditioning system to offset the heat load of the indoor environment. The refrigeration system is a crucial part of the central air-conditioning system. Its type, operation mode, structural form, etc. directly affect the economy, efficiency, and rationality of the central air-conditioning system in operation.

1 horsepower = 735W. The definition of a horse is the amount of power that can be generated by inputting 1 horsepower. Generally speaking, the cooling capacity of one horse is roughly 2000 kcal. When converted to international units, it should be multiplied by 1.162, so the cooling capacity of one horse is 2000×1.162=2324W. The W (Watt) here represents the cooling capacity.

1.5 horsepower should be 2000×1.5×1.162=3486W, and so on, which can roughly determine the number of horses and cooling capacity of the air conditioner. Generally speaking, the cooling capacity of 2200~2600W is called one horse, the cooling capacity of 3200~3600W is called 1.5 horses, and the cooling capacity of 4500~5500W is called 2 horses.

Refrigeration ton (RT): A unit of refrigeration, also known as freezing ton. Refrigeration ton represents the cooling capacity required to freeze 1 ton of saturated water at 0°C to ice at 0°C in 24 hours.

1US.RT=3516.7W (US stands for United States)

10HP=10*2324w=23240w

23240w/3516.7W=6.6US.RT

一、Common air conditioning systems

Wall-mounted air conditioner: usually called split air conditioner, it is not restricted by the installation location and is easier to match with urban decoration. There is less noise. Some split air conditioners have multiple purification functions that can purify indoor air. Nowadays, split air conditioners have ventilation functions to protect your health.

Standing cabinet air conditioner: high power, strong wind, suitable for large-area rooms, and can adjust the temperature of multiple rooms.

Mobile air conditioner: suitable for local cooling and can be used in many occasions: kitchen, living room, construction site, office, etc.

One-to-many air conditioner: It is actually a large branch of split air conditioner. It has multiple indoor units and can be used in multiple rooms, but shares one outdoor unit. It is cheaper than buying multiple air conditioners and makes less noise, eliminating the trouble of installing multiple outdoor units.

Electric refrigeration air conditioners are the most commonly used form of air conditioning. Let’s talk about the classification of electric refrigeration air conditioners according to cooling methods:

1. Air-cooling: The condenser uses forced air convection to exchange heat. This is basically the case for household air conditioners. There are two types of air-cooled air conditioners: single-cooling type and heat pump type. As the name suggests, the single-cooling type can only be used for cooling in summer. Heat pumps The model can both cool in summer and heat in winter.

2. Water cooling: The heat emitted from the condenser is cooled by water flow. In order to save water, the cooling water from the condenser is transported to the cooling water tower by a water pump, and returns to the condenser after exchanging heat with the air. Water cooling systems generally can only provide cooling.

二、Classification according to the form of host compressor

1. Piston compressor: It was a compressor that was commonly used in early air conditioners. Because there were too many parts, the failure rate was high, the production cost was relatively high, the operation stability was poor, and the compressor’s ability to resist liquid shock was poor. Now it has rarely use.

2. Rolling rotor compressor: widely used in household appliances, refrigerators and air conditioners, among which large and medium-sized rolling rotor compressors are also used in cold storage. There are few parts, simple structure, few wearing parts, reliable operation, no suction valve plate, high processing accuracy requirements, and large leakage, friction and wear between the slide plate and the cylinder wall, which limits its working life. and efficiency improvements.

3. Scroll compressor: A type of compressor that is currently used frequently. The compressor consists of four parts: a fixed plate, a moving plate, a motor, and a body. Its biggest feature is that it has fewer parts, high operating stability, and is easy to use. It has a long life and is widely used in small refrigeration units, such as modular machines and household air conditioners mentioned later.

4. Screw compressor: The most frequently used compressor on large central air-conditioning hosts. It is characterized by fewer parts, high stability, long service life, and easy maintenance. Another very important point is the energy efficiency of the screw compressor. The ratio is very high. With the same cooling capacity, the screw machine saves more than 25% energy than the piston machine. Screw machines are divided into single screw and twin screw.

5. Centrifugal compressor: The appearance of the centrifuge looks like a large centrifugal water pump, and its structure is similar to that of a water pump. Centrifugal compressors are often used in central air-conditioning hosts with relatively high power. They are characterized by large cooling capacity per unit, simple structure, reliable performance and stable operation. Due to their high requirements on the production process.

三、Different classifications of indoor systems

1. Fluorine system: The indoor unit and the host are connected by copper pipes. The refrigerant runs in the copper pipes. The refrigerant directly evaporates and absorbs heat in the indoor unit. It is often used in household air conditioners and commercial air conditioners. Due to its characteristics, the system cannot be made very large.

2. Water system: The indoor system and the host are connected by water pipes. Low-temperature water (7°C) runs in the pipes. The low-temperature water absorbs heat from the indoor unit (fan coil unit) and flows back to the host. It is most widely used in large central air conditioning systems.

3. Air system: The air handler directly processes the air to the required temperature, and then sends the air to the required room through the air duct channel. The characteristic is that it is easy to introduce new air. There are certain requirements for the height of the space during installation, and at the same time, it is less economical.

1. Screw water-cooled chiller has large cooling capacity;

2. Scroll water-cooled chillers are rarely used;

3. The centrifugal water-cooled chiller has a large cooling capacity;

4. The air-cooled screw cold water heat pump unit has a large cooling capacity and does not require a special machine room for a cooling tower;

5. The air-cooled module cold water heat pump unit has a moderate cooling capacity and does not require a dedicated machine room for a cooling tower;

6. The large air-cooled vortex cold water heat pump unit has a large cooling capacity and is the same form as the air-cooled module;

7. Small household water system air conditioning unit has small cooling capacity and is suitable for home use;

8. Small variable frequency multi-link air conditioning unit with small cooling capacity suitable for home use;

9. Medium and large variable frequency multi-unit air conditioning units with large cooling capacity are suitable for use in various places.

四、 Simple and quick calculation of project models

Cooling load index method per unit area

Q=Q’*S (fluorine machine)

QTotal cooling load of air-conditioned rooms in the building (w)

Q’ cooling load index (w/m2)

S air-conditioned room area (m2)

Q=Q’*S*80% (water machine)

Q Total cooling load of air-conditioned rooms in the building (w)

Q’ cooling load index (w/m2)

S air-conditioned room area (m2)

Project calculation question: How much refrigeration capacity of fluorine machine is required for a shopping mall of 1500m2?

S (air-conditioned room area)=1500*80%=1200m²

Q’ (cooling load index) =200 (w/m2)

Q (Total cooling load of air-conditioned rooms in the building) =S*Q’

= 1200*200=240000(w)=240(kw)

Project calculation question: How much cooling capacity does a modular machine need for a shopping mall of 1500m²?

S (air-conditioned room area)=1500*80%=1200m²

Q’ (cooling load index) =200 (w/m2)

Q (total cooling load of air-conditioned rooms in the building) =S*Q ’*80%

= 1200*200*80% =192000(w)=192(kw)

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский