Product Name:Rotary Heat Recovery Fresh Air Unit

Scope of Application:

● Airflow range: 200-1000m3/h

● Commercial air-conditioning systems:

Star hotels, high-grade office buildings, centralized heating and cooling residential buildings, large supermarkets, bus stations, railway stations, airplane waiting rooms, hospitals, indoor gymnasiums, swimming pools and so on.

●Industrial air-conditioning systems:

Printing machinery, paper, textile, pharmaceutical, food, electronics, etc.

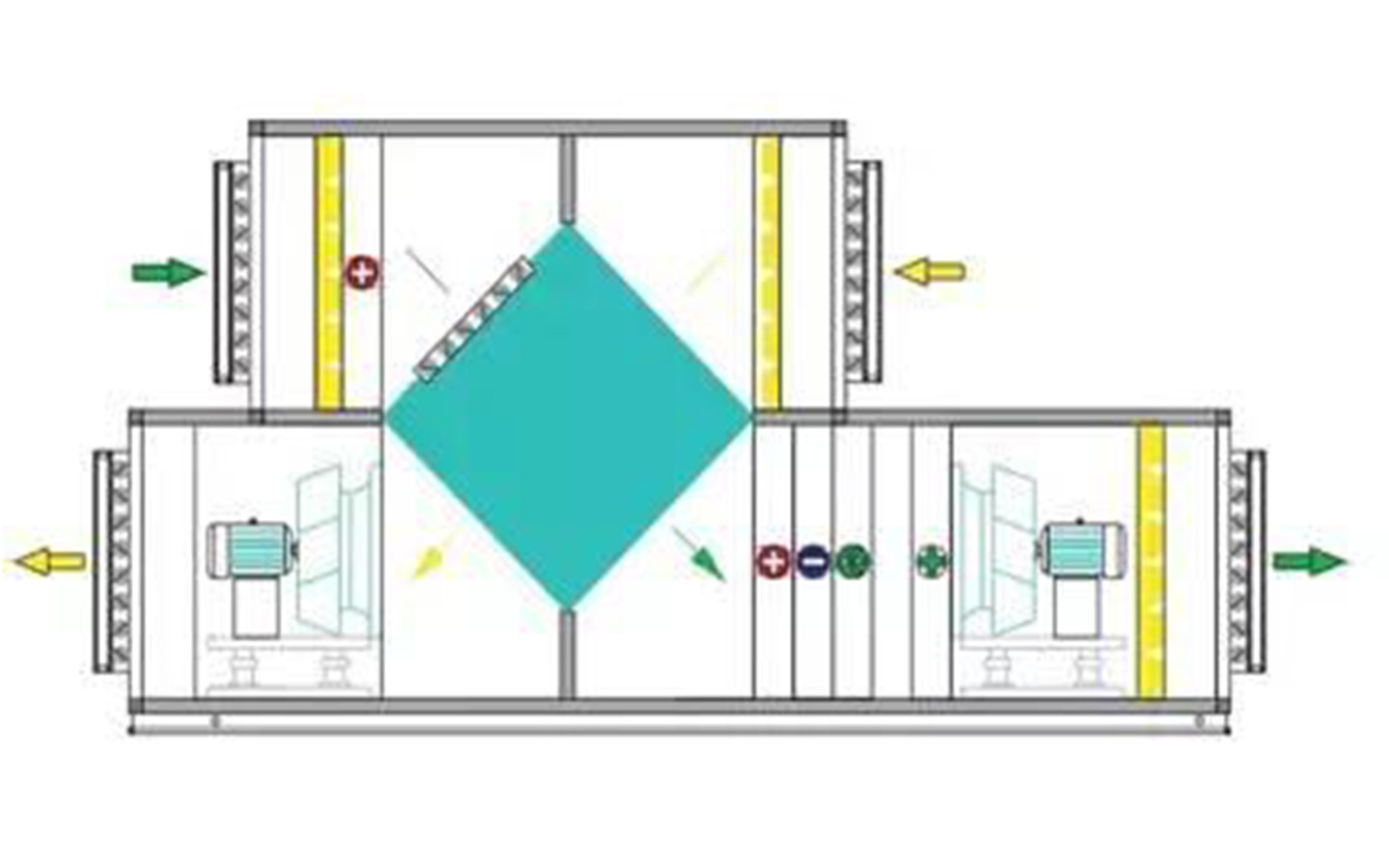

Working Principle:

The main part of the rotary heat exchanger is a disc-shaped heat storage wheel, made of aluminum foil wound into a honeycomb as a heat storage body. When working, the new air through the heat exchanger of a half-circle, exhaust air at the same time reverse through the other half-circle, the heat storage wheel under the action of the power agencies, to about 10 rpm speed of continuous rotation, the heat storage body is heated in the high temperature side of the half-circle, absorbing heat; rotating to the low-temperature side of the half-circle is cooled, releasing heat. So week after week, part of the energy in the exhaust air (cold, heat) recycling to the new air in the aluminum foil surface coated with moisture-absorbing materials, made of all-heat type rotor, the moisture in the airflow into the moisture-absorbent coating, when the rotor to the other airflow when the moisture is released, the rotary heat exchanger achievement is the use of fresh air and exhaust air through the exchange of sensible and latent heat and energy recovery, to achieve energy saving and maintain good ventilation, summer It can pre-cool and dehumidify the fresh air in summer and preheat and humidify the fresh air in winter.

Main function:

● The heat exchange rate is as high as 70%-90%;

●The content of desiccant in the rotary core is high, and the effect of moisture transfer is remarkable;

●The coating of molecular sieve adopts the patented sintering technology, which is not easy to peel off, and the heat transfer, and the effect of mass transfer is remarkable;

●Single rotor wind area is large, thickness is small, resistance is small, covers an area of small, easy to combine with other functional sections of the air conditioning unit;Self-cleaning function and cleaning fan surface, more durable use

Product Characteristics:

1. The heat recovery rate is above 81.5% and the pressure drop through the exchange is 200 Pa.

2. The rotor heat exchanger has an appreciable temperature efficiency at 12 rpm and a humidity efficiency of about 20 rpm.

3. The rotor has two purposes: total heat recovery and sensible heat recovery.

4. The installation of the rotor has a lower electrical load, which realizes energy saving, without the need of installing inlet air reheating equipment, and improves the conditions of the surface cooler and thermal insulation.

5. The rotor core is made of special alloy aluminum with high heat transfer coefficient, chlorine and

corrosion resistance, and long service life.

6. Structure: Integral winding + fixed spoke structure. Non-glue pasting, firm and stable structure, service life can be more than 15 years, can be cleaned by high-pressure air, also can be cleaned by water, steam and solution.

7. The frame of the unit is equipped with heat insulation and anti-cold bridge, all metals inside the box of the air handling unit are isolated from the outside metal by polyurethane foam and specially designed rubber sealing strip, and fit tightly with the panel with low air leakage rate.

8. solid structural design: the unit is connected by aluminum alloy profiles and cast aluminum inserts, with high overall strength; meanwhile, the square steel frame is designed inside the unit according to different wind volumes and pressures, which further strengthens the strength of the unit.

9. Polyurethane heat preservation: the panel is composed of polyurethane foam with extremely low thermal conductivity and two layers of steel plates inside and outside with a density of 50kg/m3. The standard panel thickness is 25mm, 35mm and 50mm.

10. The fan and motor components are equipped with unique vibration-damping devices, and a flexible connection is adopted between the air outlet of the fan and the panel, thus minimizing both vibration and noise of the unit. The unique sealing structure prevents the noise from being transmitted out of the unit, so we provide you with a quiet running unit to meet the different requirements of various industries.

11.The cabinet of the unit adopts double-surface plate structure, the thickness of outer wall plate is ≥0.5mm, the thickness of inner wall plate is ≥0.6mm, and the thickness of panel is 50mm. the heat insulation layer of the cabinet adopts flame-retardant polyurethane foam. The inner surface of the unit can be cleaned and sterilized regularly to ensure air quality, and at the same time ensure the best thermal insulation and vibration and noise reduction. The panels and frames are designed for easy disassembly.

12. Thickness of aluminum foil of fin 0.13mm, copper tube ¢15.8×0.5mm, heat transfer coefficient ≥54m2W/℃.

13. The unit is tested for more than 2 times before leaving the factory, and the test pressure is 2.8Mp.

14. The rotor unit can be produced as a complete set without purchasing other supporting equipment.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский