Centrifugal blowers are widely used in various applications for moving air or gas. Among different types of centrifugal blowers, C-type and D-type blowers exhibit distinct differences in their structural design and performance characteristics.

Centrifugal blowers are widely used in various applications for moving air or gas. Among different types of centrifugal blowers, C-type and D-type blowers exhibit distinct differences in their structural design and performance characteristics.

Structural Design:

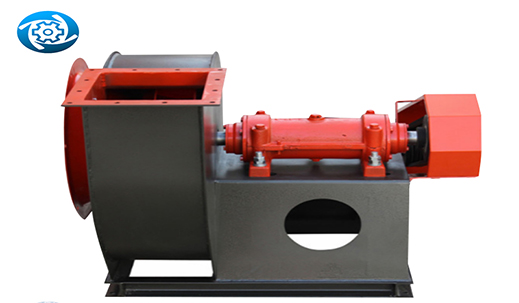

C-Type Centrifugal Blower:

The C-type centrifugal blower features a large circular spiral casing. The inlet is positioned at the center of the blower, while the outlet is located at the periphery of the casing. The impeller, typically a smaller diameter circular shape, is situated at the center of the casing.

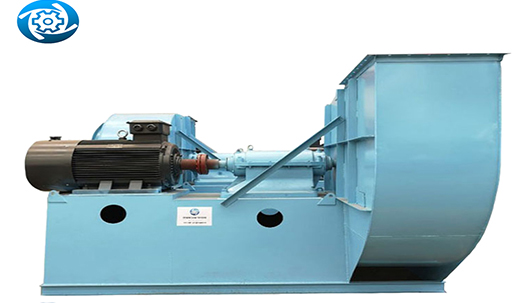

D-Type Centrifugal Blower:

The D-type centrifugal blower is characterized by a smaller circular spiral casing. Both the inlet and outlet are symmetrically positioned on the casing. The impeller, usually a larger diameter circular shape, is located on one side of the casing.

Impeller Design:

C-Type Centrifugal Blower:

The impeller of a C-type blower typically has a smaller diameter with higher blade curvature, resulting in a bent appearance. This design facilitates high airflow capacity and lower static pressure.

D-Type Centrifugal Blower:

The impeller of a D-type blower typically has a larger diameter with lower blade curvature, resulting in a flatter appearance. This design enables higher static pressure and lower airflow capacity.

Application Areas:

C-Type Centrifugal Blower:

C-type blowers are well-suited for applications requiring high airflow capacity and low static pressure. They are commonly used in ventilation systems, air circulation in HVAC systems, and similar applications.

D-Type Centrifugal Blower:

D-type blowers are suitable for applications requiring higher static pressure and lower airflow capacity. They find applications in industrial processes such as dust extraction and gas conveying.

Efficiency and Noise:

C-Type Centrifugal Blower:

Due to its design characteristics, C-type blowers typically exhibit higher efficiency at high airflow conditions. However, they may generate higher noise levels at high static pressure conditions.

D-Type Centrifugal Blower:

D-type blowers generally maintain higher efficiency at high static pressure conditions and lower noise levels at lower airflow conditions.

Conclusion:

In summary, C-type and D-type centrifugal blowers differ in terms of their structural design, impeller characteristics, application areas, efficiency, and noise levels. Understanding these distinctions is crucial when selecting the appropriate blower for specific requirements. Whether it’s a need for high airflow or high static pressure, choosing the right centrifugal blower type ensures optimal performance in various applications.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский