Embrace the Challenge: High-Temperature Endurance and Wear Resistance

Display a vibrant picture showcasing Decent Machinery’s durable wear-resistant centrifugal fan.

Display a vibrant picture showcasing Decent Machinery’s durable wear-resistant centrifugal fan.

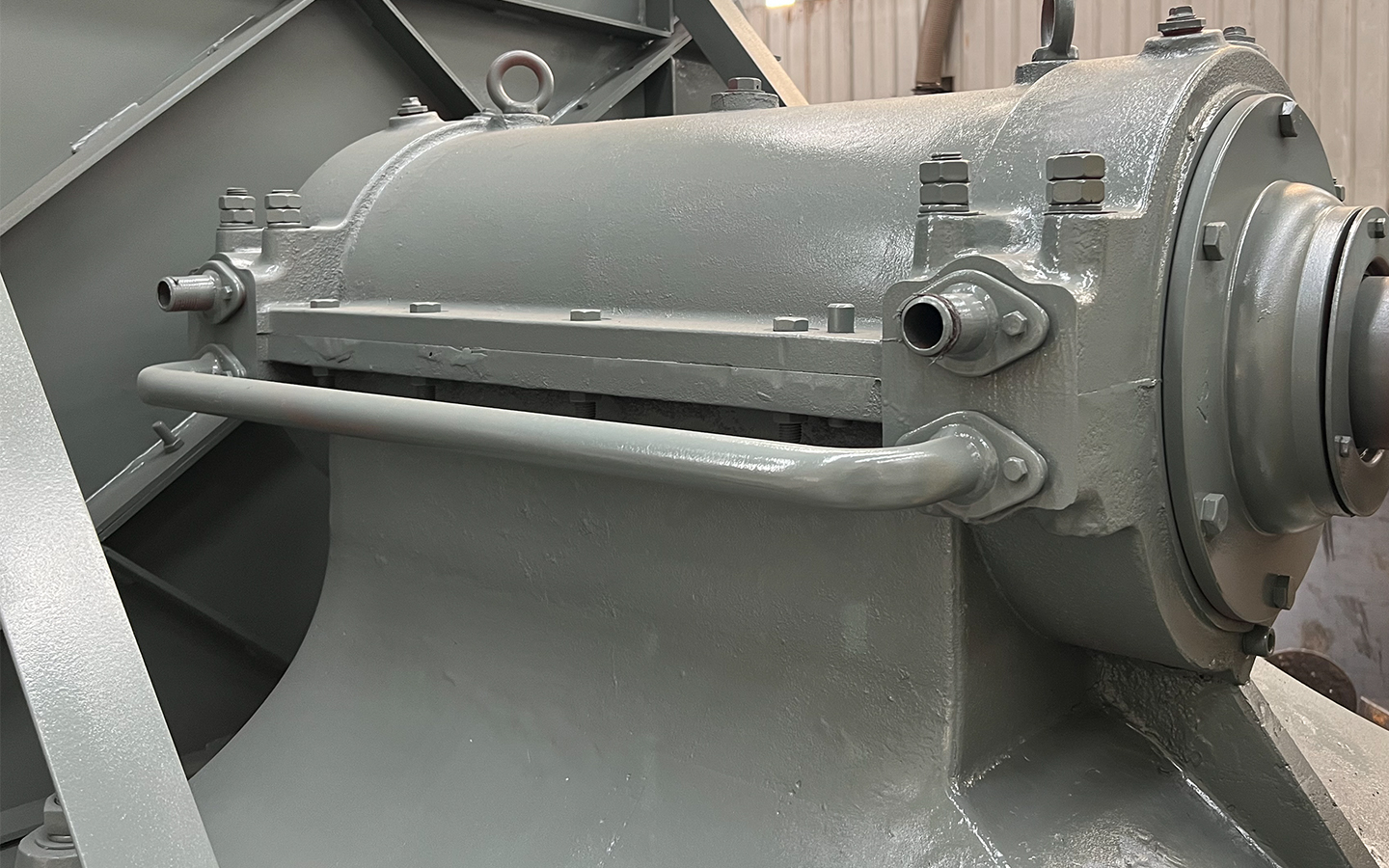

Showcase an appealing image of Decent Machinery’s innovative water-cooled bearing housing.

Showcase an appealing image of Decent Machinery’s innovative water-cooled bearing housing.

When it comes to boiler applications, Decent Machinery offers exceptional centrifugal fans designed to withstand high temperatures and combat wear and tear. Our Indonesian clients demand superior performance in extreme conditions, emphasizing the importance of high-temperature resilience and wear resistance. In response, Decent Machinery has engineered an unmatched solution, combining advanced materials, innovative cooling technology, and wear-resistant design.

Mastering High-Temperature Challenges: Engineered for Extremes

Imagine Decent Machinery’s wear-resistant centrifugal fan, meticulously crafted to endure the harshest thermal environments. Through careful material selection, we ensure our fans can withstand scorching temperatures up to 320 degrees Celsius, ensuring optimal functionality and reliability in demanding heat-intensive scenarios.

Cooling Redefined: Water-Cooled Bearings for Optimal Heat Dissipation

Discover Decent Machinery’s groundbreaking water-cooled bearing housings, revolutionizing cooling efficiency. By utilizing water as a cooling medium, our innovative design effectively dissipates the heat generated during fan operation. This redefined cooling mechanism ensures safe operating temperatures and extends the fan’s lifespan, eliminating concerns of overheating.

Defying Wear and Tear: Customized Solutions for Particle Resilience

Experience the power of wear-resistant design: Decent Machinery’s centrifugal fans are engineered to combat wear and tear caused by solid and adhesive particles. Our specialized impeller blades, enhanced with wear-resistant welding rods, mitigate damage and ensure uninterrupted operation, maximizing fan longevity.

Customization Unleashed: Tailoring to Your Particle Requirements

Decent Machinery understands the diverse particle compositions encountered in boiler applications. We offer customizable wear-resistant patterns, tailored to your specific needs. Whether you require vertical or serpentine patterns, our centrifugal fans are optimized to handle various particle scenarios, ensuring optimal performance and durability.

Welcome to a World of Unmatched Performance: Elevate Your Boiler System with Decent Machinery’s Wear-Resistant Centrifugal Fans. With high-temperature resilience and exceptional wear resistance, our fans excel in demanding environments, surpassing expectations. Trust in Decent Machinery’s expertise to optimize your boiler system, minimizing maintenance costs and maximizing customer satisfaction.

Welcome to a World of Unmatched Performance: Elevate Your Boiler System with Decent Machinery’s Wear-Resistant Centrifugal Fans. With high-temperature resilience and exceptional wear resistance, our fans excel in demanding environments, surpassing expectations. Trust in Decent Machinery’s expertise to optimize your boiler system, minimizing maintenance costs and maximizing customer satisfaction.

In addition, we offer the following specifications for wear-resistant steel plates:

| AR400 | AR450 | AR500 | NM360 | NM400 |

| NM450 | NM450 | Hardox 400 | Hardox 450 | Hardox 500 |

Our wear-resistant steel plates can be customized to meet your specific requirements and are equipped with advanced material engineering and innovative cooling technologies. Whether facing high-temperature environments or stubborn abrasion, these wear-resistant steel plates ensure stable functionality and reliability. Decent Machinery is committed to providing you with optimal performance and durability for your success, which is why we offer a variety of wear-resistant steel plate specifications to meet different application needs.

Please note that it is recommended to select suitable wear-resistant steel plate specifications based on specific projects and engineering requirements. Our professional team will work with you to ensure the best wear-resistant steel plate solution is provided.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский