Product Description:

The FGACZ series axial flow fan is an exceptionally efficient and secure ventilator designed specifically for mining operations. Tailored to meet the demands of large mines, it serves as a primary ventilator for both large and medium-sized mine shafts. This ventilator boasts an external motor structure, enabling hassle-free user maintenance. Featuring a sophisticated blade adjustment system and outstanding aerodynamic performance, this series ensures smooth operation, minimal noise, and a wide operational range. It stands as an ideal ventilation solution for coal mines, metal mines, and other mining environments. Especially well-suited for high-volume mines driven by fully mechanized mining machinery.

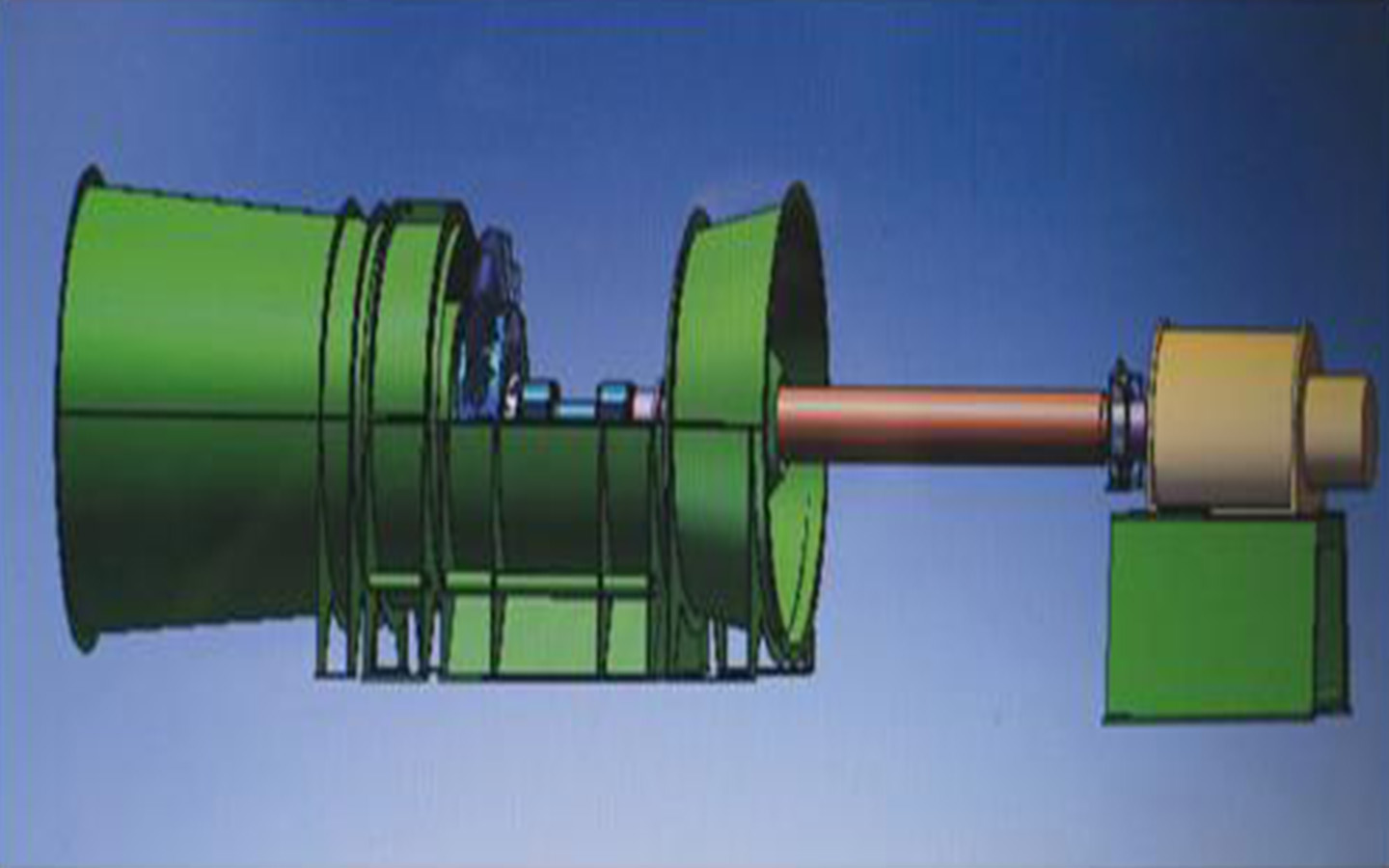

Structural Features:

1.Comprising a current collector, main body, diffuser, transmission shaft, motor, and other essential components, the fan is typically housed within a machine room. Equipped with lifting apparatus for convenient installation and maintenance, each component is securely affixed to the cement foundation with soft connections to mitigate vibration transmission.

2.Driven by a single motor installed externally through the elongated axis, this fan’s design is particularly adaptive to large mines with varying power requirements across operational stages. Its design flexibility isn’t restricted by motor size, allowing for the utilization of different motors as per specific needs, ensuring cost savings, energy efficiency, and hassle-free replacement.

3.The FGACZ series fans are meticulously selected based on mine working condition parameters and can be configured with either a single or double impeller. Equipped with guide vanes at the front and rear, these fans significantly enhance overall efficiency.

4.Equipped with an easily operated electric brake system, this fan facilitates swift wind reversal. The reversal process is completed within 5 minutes, achieving over 60% of the normal air volume in reverse.

5.The fan features non-stop refueling and oil draining mechanisms, allowing for seamless lubricating oil addition during operation.

6.Embedded temperature and vibration measuring elements between the fan bearing seat, bearings, and stator windings of the motor provide real-time temperature and vibration data for various fan components during operation.

7.Crafted from precision-machined forged aluminum alloy, the blades undergo meticulous multi-axis CNC machining, ensuring consistency in blade shape on the same hub, thereby significantly enhancing aerodynamic performance.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский