When considering the purchase of our mechanical equipment, such as Centrifugal Fan Blowers, Mine Fans, Tunnel Fans, AHUs (Air Handling Units), and HVAC (Heating, Ventilation, and Air Conditioning) Systems, you can rest assured that our products undergo rigorous vibration testing before leaving our factory. This testing ensures compliance with the international standard ISO 10816-1, specifically tailored for equipment operating in environments where vibration sensitivity is paramount, such as the case with Centrifugal Fan Blowers, Mine Fans, Tunnel Fans, AHUs, and HVAC Systems.

Centrifugal Fan Blowers, Mine Fans, and Tunnel Fans are essential components in various industries where efficient air circulation and ventilation are critical. In these applications, ensuring proper equipment performance is of utmost importance.

I. Specific Applications of Vibration Testing:

In practical terms, vibration testing plays a pivotal role in the functionality and reliability of equipment within these categories:

1. Performance Assurance: Centrifugal Fan Blowers, Mine Fans, and Tunnel Fans all require prolonged and efficient operation to maintain indoor air quality. Vibration testing allows us to assess whether the vibration levels of these devices fall within acceptable ranges, ensuring they perform their intended functions effectively.

2. Safety Considerations: Elevated vibration levels can lead to equipment failures, impacting not only the lifespan of the equipment but also posing potential hazards to the working environment and personnel. Vibration testing aids in the early detection of underlying issues, thereby enhancing equipment safety.

3. Environmental Impact: Due to their substantial energy consumption, Centrifugal Fan Blowers, Mine Fans, and Tunnel Fans are also subject to environmental concerns. Vibration testing helps guarantee that these systems operate efficiently while minimizing unnecessary energy consumption, thus reducing their environmental footprint.

II. Specific Utilization of Vibration Monitoring Devices:

To further enhance your experience with our products, we provide Vibration Monitoring Devices as a complimentary gift to our customers. These devices serve as highly specialized tools in the maintenance of Centrifugal Fan Blowers, Mine Fans, Tunnel Fans, AHUs, and HVAC Systems:

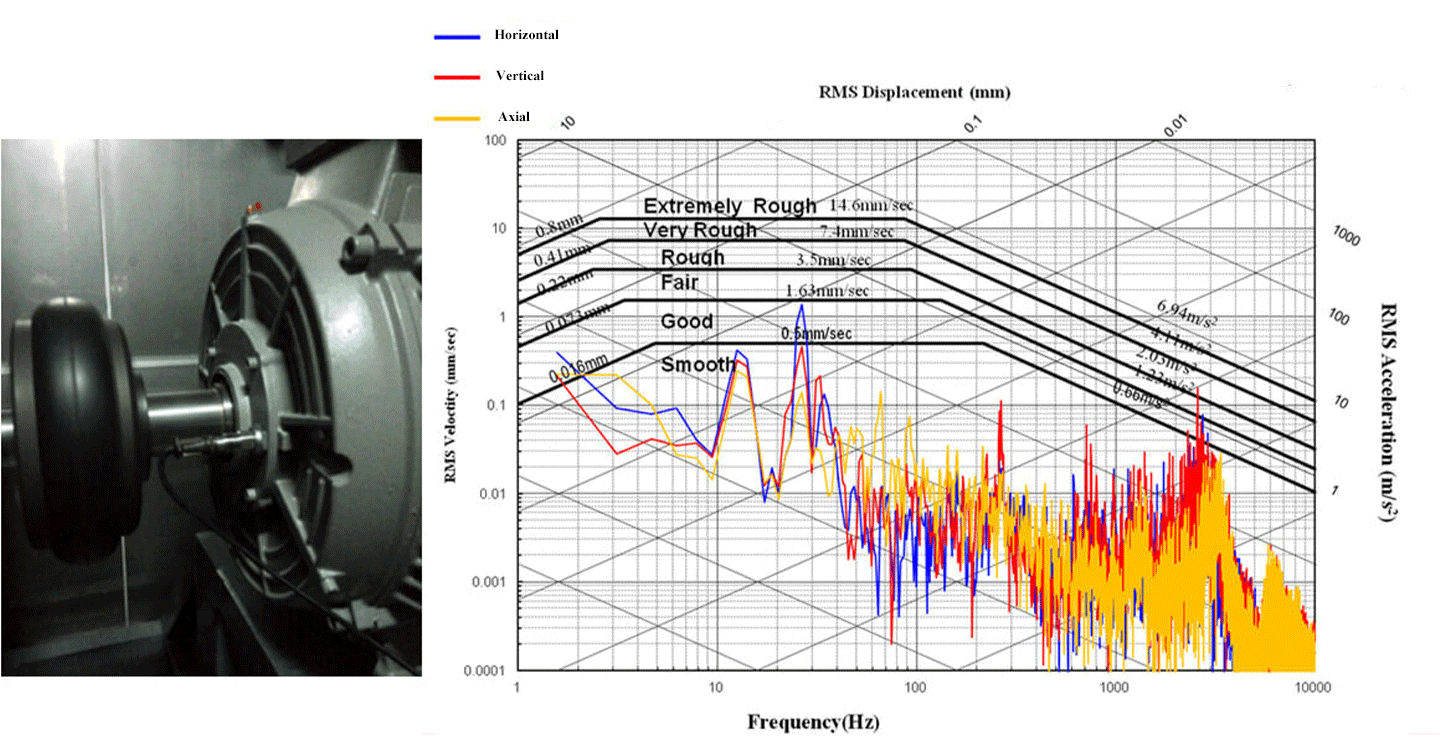

1. Real-Time Monitoring: Vibration Monitoring Devices offer continuous real-time monitoring of the vibration status of Centrifugal Fan Blowers, Mine Fans, Tunnel Fans, AHUs, and HVAC Systems. This encompasses the measurement of vibration frequency, amplitude, direction, and velocity, providing comprehensive insights into equipment performance.

2. Frequency Spectrum Analysis: These devices also facilitate frequency spectrum analysis of vibration signals, allowing for the detection and analysis of vibration patterns at various frequency ranges. This aids in identifying the nature and causes of vibration-related issues.

3. Fault Diagnosis: Vibration Monitoring Devices can identify potential fault modes, including imbalance, bearing wear, misalignment, and more. This early diagnosis enables timely maintenance interventions, reducing downtime and enhancing equipment availability.

4. Maintenance Planning: Based on the data obtained from vibration monitoring, you can develop effective maintenance plans, thereby minimizing downtime and maximizing the availability of your Centrifugal Fan Blowers, Mine Fans, Tunnel Fans, AHUs, and HVAC Systems.

III. International Standards and Detailed Vibration Requirements:

Our equipment undergoes vibration testing to ensure compliance with the detailed specifications outlined in international standard ISO 10816-1. This standard provides specific guidelines for vibration limits pertaining to various types of mechanical equipment, including Centrifugal Fan Blowers, Mine Fans, Tunnel Fans, AHUs, and HVAC Systems.

For these equipment types, specific parameters under scrutiny include:

1. Vibration Velocity: The standard dictates vibration velocity limits for different equipment types within varying frequency ranges to maintain stability and performance.

2. Vibration Amplitude: Vibration amplitude limits are determined based on the importance classification of the equipment, with higher classifications being subject to stricter limits.

3. Vibration Frequency Spectrum: The standard also prescribes methods for analyzing the frequency spectrum of vibration, aiding in the identification of vibration-related issues.

In summary, our equipment not only complies with international standards but can also be tailored to meet the specific requirements of your applications. Should you require further professional information or specific details, we are at your disposal to provide support and address any inquiries.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский