Why do we need to use chillers in industrial production?

Why do we need a chiller in industrial production? Today, DECENT Machinery will analyze the importance and inevitability of the application of chillers in the industrial industry through several aspects.

First of all, what is a chiller?

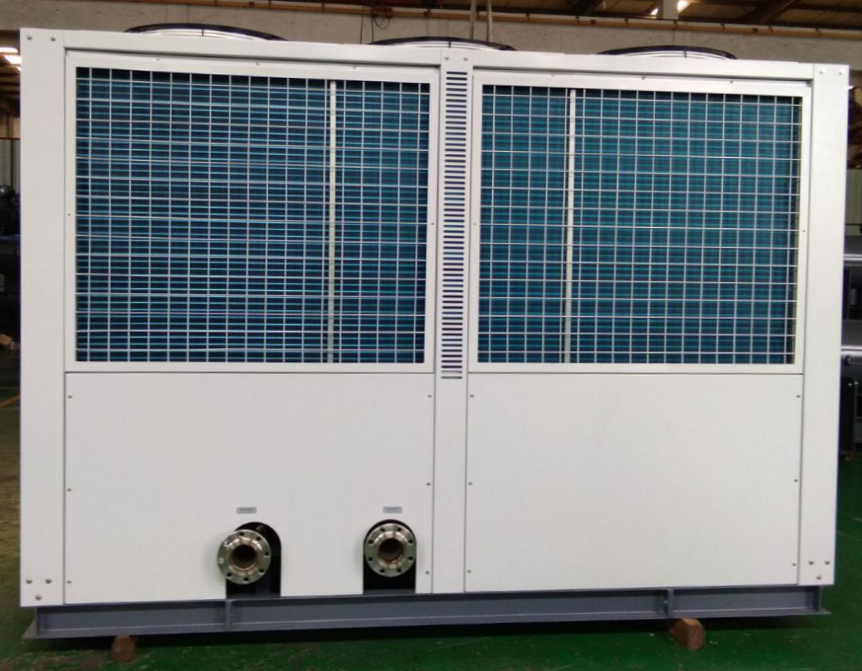

The chiller is a kind of water cooling equipment, and the chiller is a kind of cooling water equipment that can provide constant temperature, constant flow and constant pressure. The working principle of the chiller is to inject a certain amount of water into the water tank in the machine, and then cool the water through the chiller refrigeration system, and then the low-temperature cooling water is sent to the equipment to be cooled by the water pump. The chilled water takes away the heat and the temperature rises. High and then return to the water tank to achieve cooling.

The cooling water temperature can be automatically adjusted according to requirements, and long-term use can save water. Therefore, the chiller is a standard energy-saving equipment. It can also be summarized in one sentence as cooling the water at room temperature to a certain temperature through the compressor of the chiller to enhance cooling of the mold or machine. The general output temperature of cold water is 5 degrees, and customers can special request the output temperature to 0 degrees.

Why do we need to use chillers in industrial production?

In the production process, due to the continuous heat generated by machinery, molds and industrial reactions, when the temperature exceeds the material’s tolerance, the product quality is unstable. Take plastic products and electroplating production as examples. In the production of plastic products, the cooling time accounts for more than 80% of the whole cycle, and the importance of reducing the cooling time can be seen from this.

The chilled water can absorb heat in time, so that the temperature of the mold cavity can be quickly reduced, and the product shaping can be accelerated, and the opening surface can be shortened. In electroplating production, chilled water can reduce the temperature of the electroplating solution and keep the temperature constant within a certain range, so that metal molecules can quickly attach to the surface of the plated part with a stable current, so that the product is smooth and dense.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский