The difference between blower and induced draft fan:

Simply put, a blower blows air, and an induced draft fan blows air.

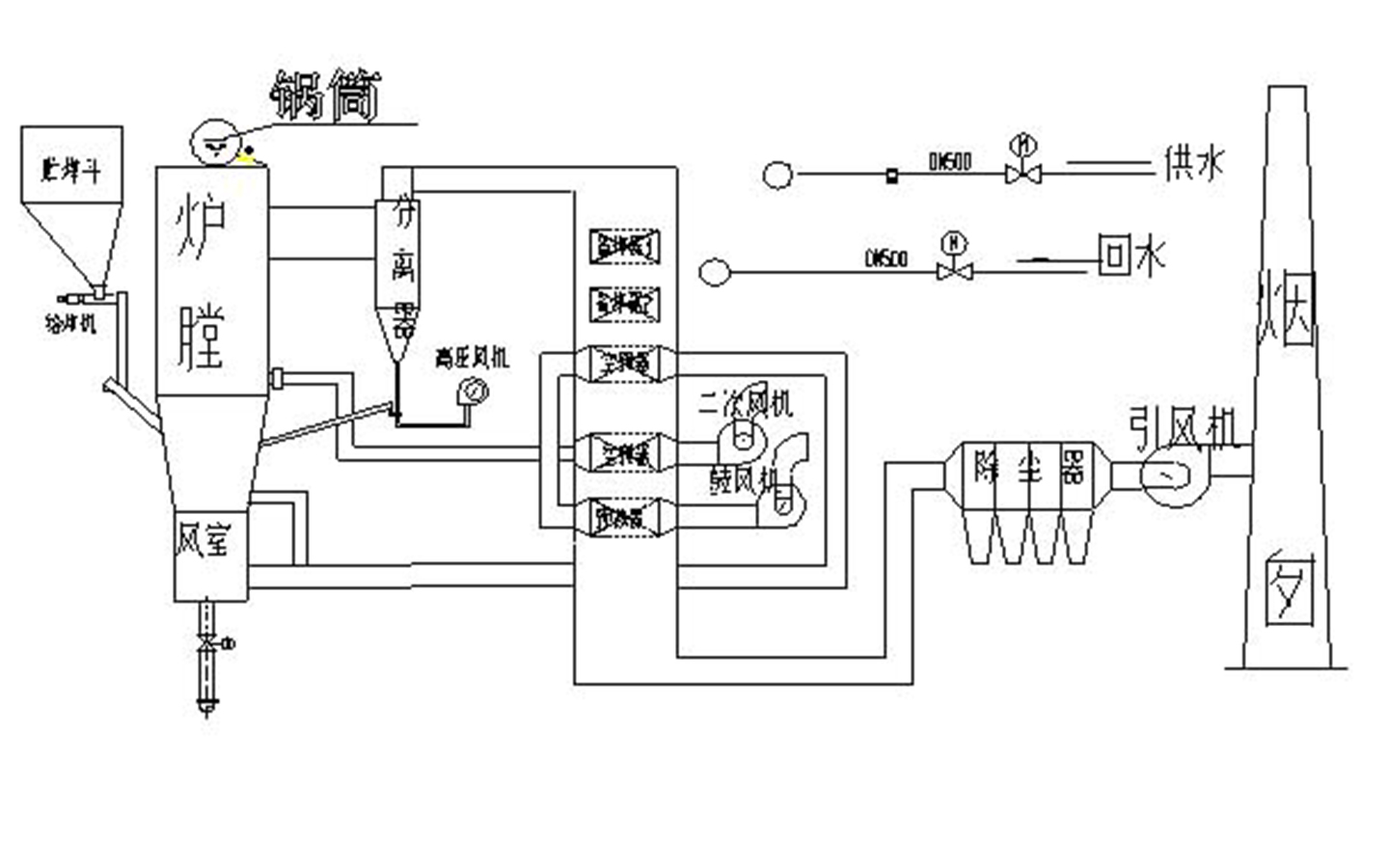

Blower and induced draft fans are generally used in boiler equipment. The induced draft fan is installed at the end of the boiler to extract the hot flue gas from the furnace; the blower is installed at the head end of the boiler to blow fresh air into the boiler.

Axial flow fans are called axial flow fans when the direction of the wind flow is parallel to the axis. For example, electric fans and outdoor air conditioner fans operate in axial flow model.

Axial flow fans, also called local ventilators, are commonly used in industrial and mining enterprises. They are different from ordinary fans in that the motor and blades are in a cylinder. The shape is cylindrical. It is used for local ventilation and is easy to install. The ventilation effect is obvious and safe, and a hairdryer can be connected to send the air to the designated area.

Axial flow fan uses:

It can be used for ventilation or heat dissipation in places such as metallurgy, chemical industry, light industry, food, medicine and civil buildings. If the casing is removed, it can also be used as a free fan, or it can be connected in series at intervals in a long exhaust duct. Installed to increase wind pressure in ducts.

Axial flow fan features:

This series of axial flow fans has the characteristics of simple structure, stability and reliability, low noise and wide range of function selection.

Centrifugal fan: The axis of the blades is not parallel to the direction of the air flow, which is a centrifugal fan.

Blower and induced draft fan are explained with an example:

If used on a boiler, the induced draft fan is installed at the end of the boiler to extract the hot flue gas from the furnace; the blower is installed at the head end of the boiler to blow fresh air into the boiler. The difference is not very big. Generally, the pressure required by the blower is generally greater than that of the induced draft fan.

The difference between axial flow fans and cabinet centrifugal fans:

Mainly in the mechanical structure of the fan:

The blade diameter of the axial flow fan is limited to the diameter of the casing, while the centrifugal fan has no such limitation. The blades can be tilted forward or backward to adapt to a wider range of air volume and pressure requirements. Moreover, the cabinet can be silenced, which has obvious advantages in terms of noise indicators.

Because the number of revolutions of the motor is generally low, the motor power is large and the power consumption is relatively high. If the ventilation system is commonly used, try to use cabinet-type centrifugal fans. For systems that are not commonly used for fire and smoke exhaust, it is more economical and reasonable to use high-temperature axial flow fans!

Centrifugal fans have more advantages than axial flow fans in the combination of large air volume and large air pressure (mainly referring to fan efficiency and noise indicators)!

The difference between centrifugal fans and axial flow fans is:

1. The centrifugal fan changes the flow direction of the medium in the air duct, while the axial flow fan does not change the flow direction of the medium in the air duct;

2. The former has large air volume and wind pressure, while the latter has low air volume and wind pressure;

3. The former is more complicated to install, while the latter is simpler to install;

4. The former motor and fan are generally connected through a shaft, while the latter motor is usually inside the fan;

5. The former is often installed at the inlet and outlet of air conditioning units, boiler drums, induced draft fans, etc., while the latter is often installed in the air duct or in front of the air duct outlet.

Mixed flow fan: Between the centrifugal fan and the axial flow fan is the axial flow fan, which combines the characteristics of the axial flow and centrifugal fans, although it looks more like a traditional axial flow fan. The curved plate blades are welded to the conical steel hub. The flow rate is varied by changing the angle of the blades in the inlet housing upstream of the impeller. The enclosure can have an open inlet, but more often it has a right-angle curved shape that allows the motor to be placed outside the pipe. The excretion shell slowly expands to slow down the flow of air or gas and convert kinetic energy into useful static pressure.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский