To determine the rotation direction of a centrifugal fan, it is necessary to stand at the position of the motor in order to correctly determine its rotation direction. There are two main situations of rotation direction, namely left rotation and right rotation. In fact, centrifugal fans can also be further divided into how many degrees of rotation they rotate. Today, we will mainly discuss the methods for determining rotation direction and angle.

Fans include centrifugal fans and axial flow fans. Regardless of the type of fan, they can be widely used in environmental engineering, painting, various factories, cooling towers, ships, mining and other places for ventilation, smoke exhaust, cooling and cooling, and can also be used for induced draft ventilation in industrial boilers and kilns with reasonable parameters such as air volume and pressure.

But if the fan wants to achieve good ventilation and efficiency in industrial production, the basic thing is to ensure the correct installation of the fan. The installation position and direction of the fan are mainly determined by the environmental conditions in which the fan is located. There are generally two situations: right-hand and left-hand rotation, also known as clockwise and counterclockwise directions. As for its judgment method, it is mainly determined from the “tail” position of the motor.

1. Rotation direction

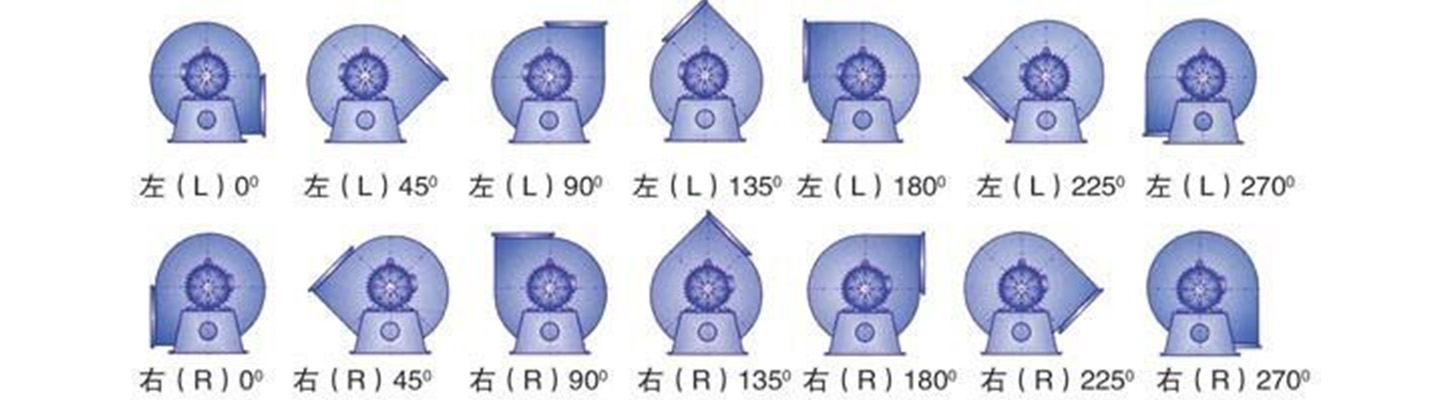

(1) When facing the inlet of the centrifugal fan, the fan impeller rotates in a clockwise direction, which indicates left rotation. If it rotates counterclockwise, it indicates that the centrifugal fan is rotating to the right.

(2) When standing at the “tail” position of the centrifugal fan motor – if the impeller rotates clockwise, it means right rotation, and if it rotates counterclockwise, it means left rotation.

The rotation direction of the centrifugal fan is also determined based on the user’s operating conditions and working environment. Only when installed correctly can the centrifugal fan convert the input mechanical energy, increase the gas pressure, and exhaust the gas, thereby accelerating the flow speed of the fan airflow, improving the efficiency of the fan, reducing time delay costs, and increasing user benefits.

2. Angle

Judging from the position of the motor’s “tail”, the air outlet is 0 ° to the ground, 90 ° vertically upwards, and 180 ° parallel to the ground. Other angles can be adjusted accordingly.

The rotation direction of a centrifugal fan is well judged. As long as the position is aligned, it is easy to distinguish. It is important to stand on the side of the bearing. If the position is reversed during installation, it can easily cause installation errors, inconvenience in use, and affect ventilation.

The following is a picture of the rotation angle of the fan

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский