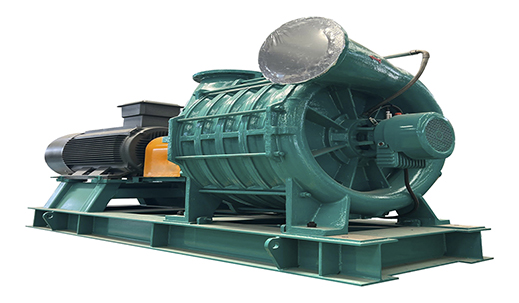

The Series C multistage centrifugal blower is a highly efficient and reliable piece of equipment used in various industrial applications. The proper installation of its inlet and outlet is crucial for ensuring optimal performance and longevity of the blower.

The Series C multistage centrifugal blower is a highly efficient and reliable piece of equipment used in various industrial applications. The proper installation of its inlet and outlet is crucial for ensuring optimal performance and longevity of the blower.

Inlet Installation:

The inlet of the multistage centrifugal blower serves as the entry point for the air or gas being drawn into the system. It is essential to follow these installation guidelines for the inlet:

a. Positioning: The inlet should be located in an area where the air or gas is relatively clean and free from contaminants. If possible, it should be positioned away from sources of dust, debris, or other pollutants that could negatively impact the blower’s performance.

b. Ductwork: Proper ductwork is necessary to connect the inlet to the air source. The duct should be appropriately sized and designed to minimize pressure losses and maximize the blower’s efficiency. Smooth bends and gradual transitions are recommended to reduce turbulence and minimize the risk of flow restriction.

c. Air Filters: Installing high-quality air filters at the inlet is essential for preventing debris, particles, and contaminants from entering the blower. Regular maintenance and replacement of these filters are necessary to ensure uninterrupted operation and avoid unnecessary strain on the blower.

Outlet Installation:

The outlet of the Series C multistage centrifugal blower is where the pressurized air or gas is discharged from the system. Consider the following guidelines for its installation:

a. Discharge Ductwork: Similar to the inlet, the discharge ductwork should be appropriately sized and designed to minimize pressure losses. It is crucial to avoid sharp bends or obstructions that could cause backpressure, reducing the blower’s efficiency.

b. Exhaust System: In applications where the discharged air or gas needs to be expelled from the facility, an exhaust system should be properly installed. This system may include additional ductwork, dampers, or exhaust fans to facilitate the safe release of the air or gas.

c. Silencers: Depending on the noise level produced by the blower, the installation of silencers in the outlet ductwork may be necessary to comply with noise regulations and minimize noise pollution in the surrounding environment.

By following the recommended,you can maximize the performance of the blower while minimizing the risk of damage or operational issues.

Español

Español Русский

Русский Tiếng Việt

Tiếng Việt 中文

中文 suomi

suomi Français

Français Português

Português English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano Português

Português Pусский

Pусский